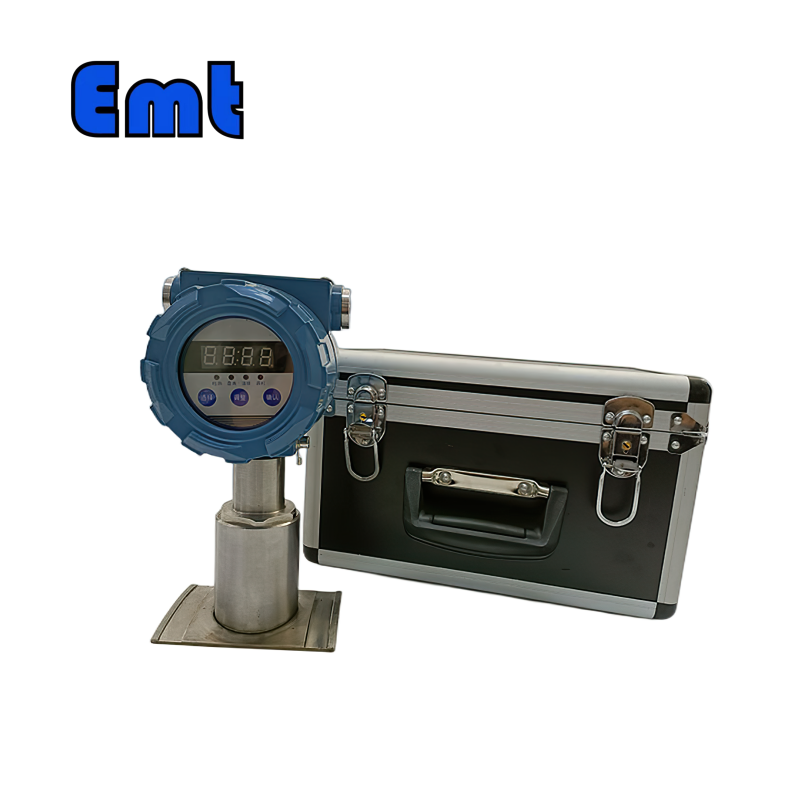

Description

Basic Features or Parameters of Removable Pig Signaler

| Name | Removable Pig Indicator with a DBB Valve |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

- Type: Intrusive

- Installing type: 2”Flange /2”Nipple welded. As per ASME B16.5 (Class 150–1500),

- Plug Body Length: Meet the actual needs

- Insert depth (In pipe): 21mm

- Operating temperature: -20~120℃ /Meet customer requirements

- NACE MR 0175: Yes

- Ingress protection: IP66

- Explosion-proof class: Exd II BT4

- Include DBB valve: Yes

- Remove under pressure: Yes (the whole machine comes with a simple retriever-two whole threaded studs)

- Trigger type: Bi-directional

- Internal part material: 316LSS is the standard configuration (DSS and INCONEL can also be provided)

- Flange/Body material: PTFE-coated A105N is standard configuration (304SS, 316LSS, DSS, INCONEL, and As per MR, can meet customer needs)

- Junction box material: aluminum alloy /316SS

- Switch type: DPDT /2*SPDT

- Switch rating: DC24V 3A /DC24V 5A

- Retriever: Two full thread studs (Special tool can be provided)

What is a DBB Valve?

A DBB valve stands for Double Block and Bleed valve. It has three positions: two closed and one open. The valve isolates a section of the pipeline. It allows you to bleed any trapped pressure. This ensures safe maintenance and inspection.

DBB valves enhance safety in pipelines. They prevent leaks and contamination. You can perform maintenance without shutting down the entire system. This increases operational efficiency. DBB valves also help in complying with safety regulations. They are crucial for reliable pipeline management.

Design and Construction

- Materials Used

- Common Materials for Durability

- Corrosion Resistance Considerations

- Structural Features

- Compact Design

- Ease of Installation and Removal

Operation of Removable Pig Signaler with DBB Valve

Preparation and Setup

Pre-Installation Checks

- Verify Compatibility: Ensure the pig signaler is compatible with your pipeline system and the Double Block and Bleed (DBB) valve.

- Inspect Components: Check all components for damage or defects prior to installation.

- Pressure Requirements: Confirm the pressure rating of the pig signaler matches the system pressure.

Required Tools and Equipment

- Wrenches and spanners

- Sealing gaskets (compatible with the flange type)

- Bolts and nuts

- Special tools for pressure removal (as specified by the manufacturer)

- Personal Protective Equipment (PPE)

Installation Process

Step-by-Step Guide

- Flange Preparation: Ensure the flange on the pipeline conforms to ANSI B 16.5 standards or customized specifications.

- Gasket Placement: Place a 3.2mm sealing gasket (for RF flanges) between the pipeline flange and the pig signaler flange.

- Insertion: Insert the pig signaler’s trigger end into the pipeline.

- Securing: Fasten the pig signaler flange to the pipeline flange using appropriate bolts and nuts. Ensure all connections are tight to avoid leaks.

Ensuring Proper Sealing

- Double-check the alignment of the sealing gasket.

- Tighten bolts in a star pattern to ensure even pressure distribution and proper sealing.

Operation During Pigging

Monitoring Pig Passage

- Indicator Activation: Observe the indicator flag or digital display for signs of pig passage.

- B Display: Flag turns vertical.

- C Display: Flag turns vertical; SPDT or DPDT switch activates.

- D Display: Digital time display starts counting; SPDT or DPDT switch activates and remains active until the factory-set time elapses.

- CD Display: Flag turns vertical; SPDT or DPDT switch activates and resets based on trigger angle; digital display operates like the D display.

Adjusting and Resetting the Indicator

- For B, C, and CD displays: Loosen the four nuts under the square flange, adjust the display position, and retighten the nuts.

- For D displays: Unscrew the knurled nut, adjust the display direction, and retighten.

Removal and Maintenance

Safe Removal Procedures

- Depressurize: Ensure the pipeline section is depressurized before attempting removal.

- Use of Special Tools: For retrievable pig signalers under pressure, use the specified special tools to safely remove the core.

- For SN2-TQZ-x-REDV models: Utilize a special long bolt, standard nut, and common spanner.

- For SN2-TQZ-x-REUV models: Follow the manufacturer’s guidelines for using special tools.

Regular Maintenance Tips

- Leak Checks: Regularly inspect for leaks at the flange seat. Replace seals if necessary.

- Visual Inspection: Periodically check the external visual seals and replace if damaged.

- Manufacturer Service: Send the unit to the manufacturer for internal seal replacement and comprehensive maintenance.

- Documentation: Keep a log of maintenance activities, including inspections, adjustments, and replacements.

Applications of Removable Pig Signaler

In the oil and gas industry, removable pig signalers play a crucial role in maintaining pipeline integrity and ensuring efficient operation. These devices are essential for leak detection and corrosion monitoring by tracking the passage of specialized pigs designed to identify weaknesses or breaches within the pipeline. This allows for timely maintenance and repairs, thereby safeguarding the pipeline’s structural health and operational safety. Additionally, these signalers are vital in pressure management, ensuring that pressure-relief pigs are correctly deployed to maintain appropriate pressure levels throughout the system.

Furthermore, removable pig signalers are indispensable in the monitoring of cleaning and inspection pigs. During cleaning operations, these signalers verify the passage of pigs tasked with removing debris and buildup, ensuring that the cleaning process is thorough and effective. For inspection purposes, they track smart pigs equipped with sensors that gather detailed data about the pipeline’s interior condition. By confirming the movement and location of these inspection pigs, the signalers provide accurate data for pipeline assessments, aiding in the scheduling and efficiency of maintenance activities. This not only reduces downtime but also enhances the overall performance and reliability of the pipeline system, making removable pig signalers a critical component in the oil and gas industry.

-300x166.jpg)

-300x246.png)

Reviews

There are no reviews yet.