Description

1. Description

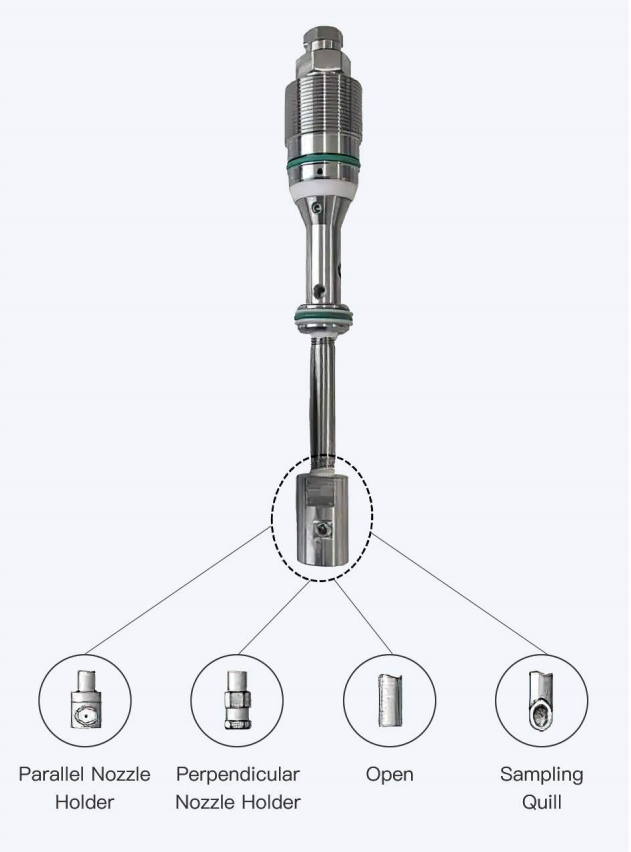

The EMT Chemical Injection Quill is designed for robust and reliable chemical injection into pipelines, crucial for maintaining system integrity and preventing corrosion. This device facilitates efficient chemical delivery under operational pressures, ensuring minimal downtime and extending the lifespan of pipeline systems. Its construction from high-grade stainless steel and compatibility with various industrial environments make it a valuable asset in harsh operational conditions.

Name | Chemical Injector Quill | |

| Material | Stainless Steel 304, Stainless Steel 316, DSS F51, Carbon Steel A105N, and also Inconel 625 | |

| Operating Temperature | -20±120 | |

| Feature | Firstly, easy Operating | |

| Secondly, high Accuracy Long Life | ||

| At last, high Efficiency, Low cost | ||

| Payment | TT/LC | |

| Advantage | Firstly, they are lightweight and flexible. | |

| Secondly, excellent Injection efficiency. | ||

| At last, accurate location tracking. |

| Model | ||||||||||||||||||||||||||||

SI | Chemical Injector Quill | |||||||||||||||||||||||||||

| -Code | Plug | |||||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | |||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | |||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | |||||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | |||||||||||||||||||||

| – Code | Injection Nut | |||||||||||||||||||||||||||

| Nxx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 3 | i.e. DSS | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 4 | i.e. INCONEL | |||||||||||||||||||||||

| – Code | Injection Tube | |||||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | ||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | i.e. No Request | The most effective position for injection is generally at the center of the pipe | ||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 1 | i.e. Open | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 2 | i.e. Quill | |||||||||||||||||||||||

| 3 | i.e. DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | i.e. INCONEL | |||||||||||||||||||||||||||

| – Code | Nipple and Valve(or end Flange)of Tee | |||||||||||||||||||||||||||

| Txx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4″Nipple | a | i.e. 1/4″Nipple and Valve | 1 | i.e. 316SS | |||||||||||||||||||||||

| 2 | i.e. 1/2″Nipple | b | i.e. 1/2″Nipple and Valve | 2 | i.e. 316LSS | |||||||||||||||||||||||

| 3 | i.e. 3/4″Nipple | c | i.e. 3/4″Nipple and Valve | 3 | i.e. D SS | |||||||||||||||||||||||

| 4 | i.e. 1″Nipple | d | i.e. 1″Nipple and Valve | 4 | i.e. INCONEL | |||||||||||||||||||||||

| 5 | i.e. 1/4″Flange | e | i.e. 1/4″Nipple end Flange | |||||||||||||||||||||||||

| 6 | i.e. 1/2″Flange | f | i.e. 1/2″Nipple end Flange | |||||||||||||||||||||||||

| 7 | i.e. 3/4″Flange | g | i.e. 3/4″Nipple end Flange | |||||||||||||||||||||||||

| 8 | i.e. 1″Flange | h | i.e. 1″Nipple end Flange | |||||||||||||||||||||||||

2. EMT Chemical Injector Quill Specification

| Category | Details |

|---|---|

| Product Information | |

| Product Name | Chemical Injection Quill |

| Brand Name | EMT Pigging |

| Condition | New |

| Type | Injection & Sampling System |

| Certification | ISO 9001 |

| Warranty | 1.5 years |

| Place of Origin | Liaoning, China |

| Physical Specifications | |

| Weight (KG) | 5 |

| Package Size (cm) | 35 x 40 x 60 |

| Gross Weight (Package, kg) | 8 |

| Material and Construction | |

| Sealing Material | Fluororubber |

| Solid Plug Assembly | 316L Stainless Steel |

| Injection Tube | 316L Stainless Steel |

| NPT Nozzle | 316L Stainless Steel |

| Flange Material | ASTM A105N |

| Operational Parameters | |

| Working Temperature (°C) | -20 to 200 |

| Operation Temperature (°C) | -20 to 150 |

| Working Pressure (LB) | 150LB, 300LB, 600LB, 900LB, 1500LB |

| Pressure Rating (PSI) | 6000 PSI or as per Flange Size |

| Applications & Industries | |

| Applicable Industries | Building Material Shops, Construction Works, Energy & Mining, Pipeline Pigging, Oil & Gas Pipeline |

| Application | Pipeline Testing |

| Quality and Compliance | |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Showroom Location | None |

| Mounting Options | |

| Mounting Types | 2″ Flange, 2″ Flareweld Access Fitting, 1″ Nipple to NPT Ball Valve |

3. Key Attributes of the EMT Chemical Injection Quill:

- Product Name: EMT Chemical Injection Quill

- Brand Name: EMT Pigging

- Condition: Brand New

- Type: Advanced Injection & Sampling System

4. Industry-Specific Attributes:

- Weight: Robust yet manageable 5 KG

- Sealing Material: High-quality Fluororubber for superior sealing performance

- Working Temperature Range: Broad range from -20°C to 200°C, accommodating extreme environmental conditions

- Working Pressure Levels: Versatile options including 150LB, 300LB, 600LB, 900LB, 1500LB to suit various pipeline specifications

- Solid Plug Assembly: Constructed from durable 316L Stainless Steel

- Injection Tube: Made from corrosion-resistant 316L Stainless Steel

- NPT Nozzle: Fabricated from 316L Stainless Steel for enhanced durability

- Flange Material: Robust ASTM A105N

5. Additional Features:

- Applicable Industries: Ideally suited for demanding environments in Building Material Shops, Construction Works, Energy & Mining, Pipeline Pigging, and Oil & Gas Pipeline applications

- Place of Origin: Manufactured with precision in Liaoning, China

- Warranty: Generous 1.5-year warranty, reflecting our commitment to quality

- Certification: ISO9001 certified, ensuring international quality standards

6. Packaging and Delivery Details:

- Selling Units: Individually packaged for optimal protection

- Package Dimensions: Compact dimensions of 35 x 40 x 60 cm

- Gross Weight: An easily transportable 8.000 kg

7. Inspection and Maintenance Capabilities:

- Video Outgoing-Inspection: Comprehensive video inspection provided, ensuring quality before shipment

- Machinery Test Report: Detailed test reports available, demonstrating adherence to performance standards

- Application: Specifically designed for high-efficiency pipeline testing

The EMT Chemical Injection Quill is designed not just to inject chemicals but to do so with unparalleled accuracy and control, allowing for the maintenance of pipeline integrity through effective corrosion management and cleaning processes. By integrating this system, industries can ensure the efficient and safe operation of pipelines, extending their operational life and reducing downtime due to maintenance. This quill system enables the continual and controlled injection of inhibitors under varying pressures, crucial for maintaining system efficiency and preventing corrosive damage in challenging industrial conditions.

Injection Quill In Pipe Cleaning

Injection Quill In Pipe Cleaning

Reviews

There are no reviews yet.