Description

Different Types of Pressure Vessel Quick Opening Closure

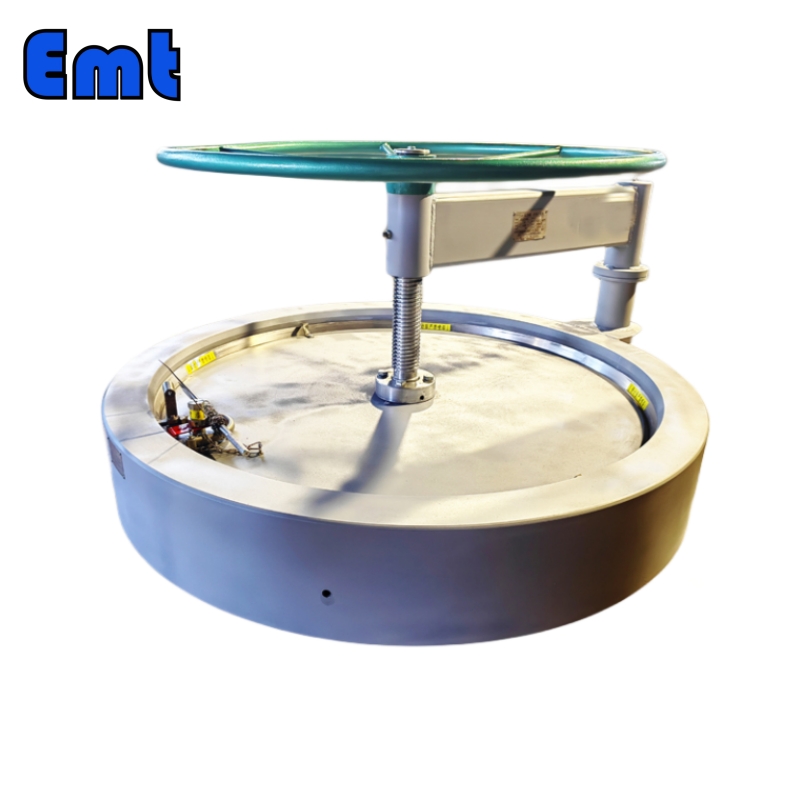

Band Lock Pressure Vessel Quick Opening Closure

A band lock type quick opening closure is a mechanical device designed for the circular openings of pressure pipelines and vessels. By turning the mechanism to one side, operators can quickly open and close these closures. This type of closure uses an inside groove locking band structure, ensuring high machining accuracy and flexibility. It features a safety interlock and a compact design, adhering to ASME code standards. Besides, this kind of product is widely utilized in the petroleum, chemical, and natural gas industries. It is essential for pig launchers, pig receivers, filter separators, and other pressure vessels.

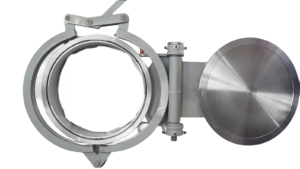

Clamp Pressure Vessel Quick Opening Closure

A clamp quick opening closure consists of a closure cover, cylinder flange, clamp hoop, sealing ring, safety interlocking mechanism, and rotary folding mechanism. This device allows quick opening and closing of pressure pipe hatches and vessel covers. It efficiently handles pig receiver and launcher covers. Operators can quickly clean or clear pipelines, enhancing transport capacity. This reduces energy consumption and ensures safe pipeline operations. Additionally, it replaces frequent switches on pipeline or container flanges. Industries such as oil refining, chemicals, medical treatment, and papermaking find it invaluable. Water supply and drainage engineering also benefit from its quick functionality.

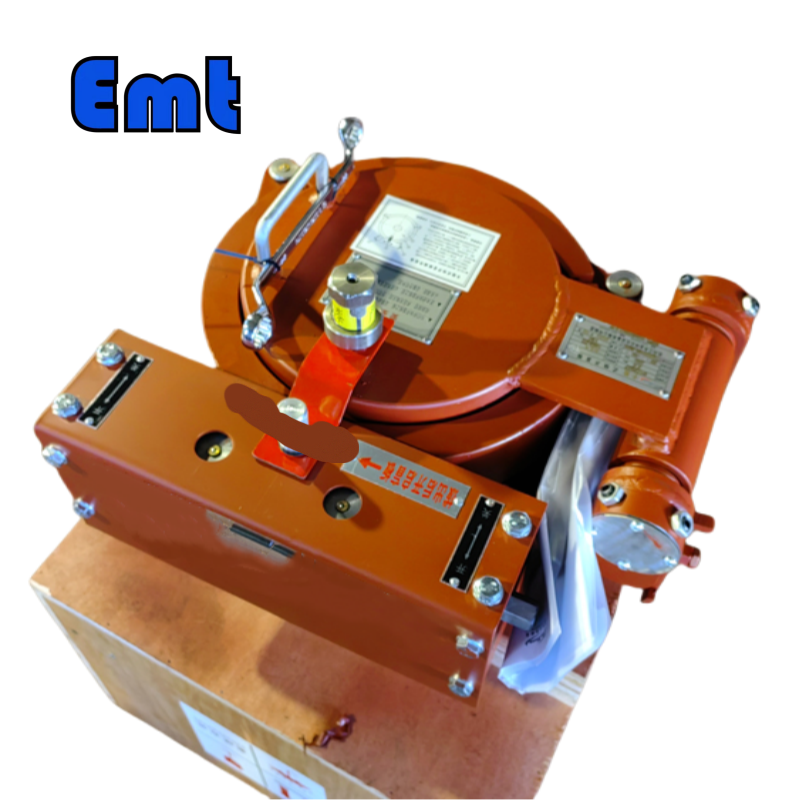

Bayonet Pressure Vessel Quick Opening Closure

A bayonet quick opening closure uses principles from traditional bayonet locks. It features a locking ring with castellated slots and a closure plug with matching lugs. To engage, rotate the locking ring 1/8th or 1/16th of a turn. This locks the closure plug securely in place. The robust design ensures quick and simple operation. Therefore, operators can manually rotate the locking ring using ergonomic handles and a manual shot bolt mechanism. For added convenience, automate the function with actuation devices and safety interlock systems. This type of closure is ideal for high-pressure testing vessels. It supports Factory Acceptance Testing (FAT) on subsea electrical connectors. Use it in both vertical and horizontal orientations for versatile applications.

Features

| Quick Opening Closures Characteristics | ||||

| Design Pressure | 1.6MPa-30MPa | |||

| Corrosion Allowance | 2mm | |||

| Seismic Fortification Intensity | 7 Degrees | |||

| Work Medium | Oil,Nature gas,Water and ore pulp etc. | |||

| Opening Time | Within 60s less than 200N | |||

| Opening Type | Vertical or Horizontal | |||

| Technical indicators | |

| Nominal Diameter DN: | <1800mm |

| Design pressure PN: | ≤40 MPa |

| Working Medium: | oil, gas, water |

| Design Temperature: | -50℃~300℃ |

| Material: | 16Mn,A350LF2, A105, SS304, SS316, F51, F53, F55, INCONEL625, HASTELLOY C |

| Pipe Thickness: | 6mm~100mm |

The Installation of Pressure Vessel Quick Opening Closure

The inner diameter of the pressure vessel quick opening closure is consistent with the inner diameter of the equipment. And the opposite gap is uniform and consistent. The difference between the maximum and minimum opposite gap should be ≤1.0 mm. The amount of the wrong side of the opposite mouth meets the requirements of Table 1 in GB150.4-2011 standard. When the wall thickness is inconsistent, the thinner of the two is calculated.

The welding type should be determined before the quick opening closure is aligned with the equipment cylinder group.

1) If double-sided welding is used, the head cover must be removed.

2) If single-side welding is used, only remove the sealing ring and do not need to remove the head cover.

Removal of Head Cover

When the head cover needs to be removed for quick opening closure assembly and maintenance, the following procedures and requirements should be followed:

- Open the head cover according to the relevant requirement

- Put the head cover in place first to avoid falling

1) Remove the setting screw at the center of the handwheel

2) Remove the handwheel

3) Remove and turn

Set the nut at the lower end of the arm shaft

4) Loosen the positioning handwheel

5) Loosen the guide nut

Then mark the removed parts and keep them safe. - With the cooperation of the crane, the shaft sleeve I, the rotating arm, and the rotating shaft are removed from the shaft sleeve II. Then place the head cover securely.

Then move it.

Special reminder: The whole process of operation, to prevent the knock, touch, scratch, and injury between the parts.

Welding And Welding Deformation Control

Due to weld shrinkage or improper welding operation in the welding process, welding deformation can be caused.

Reduce welding deformation, fast opening the closure and equipment cylinder group alignment and welding, according to the following requirements:

- The opposite gap is uniform, and the maximum and minimum opposite gap ≤ 1.0mm;

- Before welding, preheat the welding groove, preheating temperature 80~100℃, or according to the equipment welding process requirements;

- You must use the welding sequence of symmetrical welding. Because it is very important to control welding deformation;

- When welding, the operator should use small diameter electrodes, small current, and multi-layer welding methods. Minimize welding wire energy

- The welding parts on the equipment should be as far away as possible from the girth weld between the quick-opening closure and the equipment cylinder.

Suggestions for Post-welding Treatment

1. When heating the girth weld between the quick-opening closure and the equipment cylinder, use local heat treatment as much as possible.

2. If the technical requirements of the general manufacturing drawing of the equipment stipulate that the equipment must be heat-treated as a whole, rock wool.

Aluminum silicate or other insulation materials will protect the sealing surface to prevent its excessive oxidation and affect the sealing;

3. The heat treatment process according to GB150.4 Article 8.2 or ASME standards, or according to the heat treatment manufacturers’ mature heat treatment process.

4. Pay attention! Before heat treatment, the operator should remove the sealing rings. After the heat treatment, the sealing surface should be checked and a fine emery cloth should be used. Then gently wipe the sealing surface clean.

Quick Opening Closure(QOC) For Pig Launcher

Quick Opening Closure(QOC) For Pig Launcher  Quick Opening Closure For Pig Receiver

Quick Opening Closure For Pig Receiver

Reviews

There are no reviews yet.