Description

What are Pipeline Cleaning Pigs?

Pipeline cleaning pigs are essential tools for maintaining the cleanliness and efficiency of pipelines. These devices travel through the pipeline to remove sludge, debris, and other contaminants from the inner walls. Brush cleaning pigs, equipped with various styles of brushes, are particularly effective for tough deposits. They come in different shapes, like circular and block brushes, suitable for different pipeline diameters. These pigs ensure pipelines can transport gas, water, and oil efficiently by preventing blockages and contamination. Additionally, they help keep the product samples free from impurities. Brush-cleaning pigs are the ideal solution for pipelines plagued by natural blockages such as dirt and mud. They dig deep into the pipeline, ensuring thorough cleaning and optimal flow.

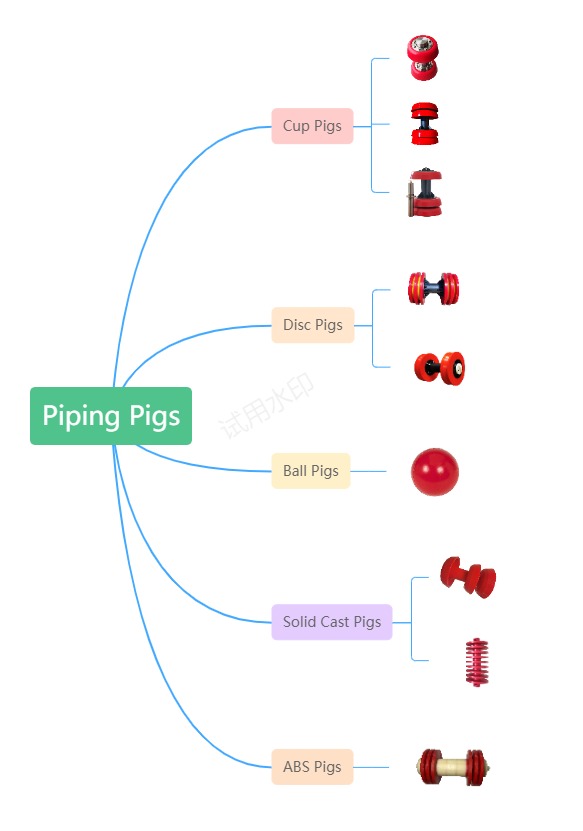

Different Types of Pigs

Foam Pigs

Foam pigs are lightweight cleaning tools used in pipelines. Made from flexible foam, they adapt easily to pipeline variations. These pigs clean by pushing out debris and contaminants as they travel. They come in various densities and can include coatings or brushes for enhanced cleaning power. Additionally, foam pigs help in pipeline drying and inspection. They are essential for maintaining pipeline efficiency and safety.

Mechanical Pigs

Mechanical pigs are robust pipeline cleaning devices built with moving parts. They physically scrape and brush the pipeline’s interior surfaces. These pigs often feature metal brushes or blades to tackle tough deposits. They excel in tasks like heavy-duty cleaning and obstruction removal. Moreover, mechanical pigs can inspect pipe integrity as they move. Operators frequently use them to ensure pipelines remain clear and functional, crucial for maintaining optimal flow and safety.

Solid Cast Pigs

Solid cast pigs are durable pipeline tools crafted from solid polyurethane or rubber. They excel in sealing and sweeping tasks. These pigs effectively remove debris and perform batch separation in pipelines. Their sturdy construction allows for extensive reuse and versatility in various applications. Moreover, solid cast pigs can also inspect pipelines for integrity and wear. Operators rely on them for efficient and reliable pipeline maintenance, ensuring long-term operational effectiveness.

Importance of Pipeline Pigging

Pipeline pigging plays a crucial role in the maintenance and efficiency of pipeline systems. Regular pigging ensures the removal of debris and buildup, which can cause blockages and corrosion over time. Additionally, this process helps maintain the optimal flow of fluids, reducing the energy required for pumping and thereby lowering operational costs.

Furthermore, pigging enhances product quality by preventing contamination. Different products traveling through the same pipeline can mix without proper cleaning, leading to quality issues. Pigging ensures each batch remains pure and uncontaminated. It also extends the life of the pipeline by preventing the accumulation of harmful substances that can degrade the pipeline material.

Moreover, pigging contributes to safety by reducing the likelihood of pipeline failures and leaks. Regular removal of deposits and inspections help identify potential weaknesses before they lead to serious problems. This proactive maintenance approach not only saves money on repairs but also protects the environment from potential spills and pollution.

In conclusion, the importance of pipeline pigging cannot be overstated. It ensures operational efficiency, product purity, and safety—all vital for the long-term sustainability of pipeline operations. Implementing a regular pigging schedule is essential for any pipeline management strategy.

Specifications

| Polly Foam Pig | LCQZ-RTR | 1. Its interior is foamed by polyurethane material. The surface is coated with a polyurethane elastomer coating. | Starting pressure: 0.02 MPa |

| 2. Good flexibility and certain wear resistance. | Density: 35 kg/m³~220 kg/m³ | ||

| 3. The deformation amount can reach 50%. Which is the most widely used foam pig. | Withstand pressure: 7 MPa | ||

| 4. Used for scrubbing, descaling, and fluid isolation of pipes. | Stretch rate: 320% | ||

| Compression ratio: 50 | |||

| Flex life: 50,000 times | |||

| Attrition rate: 2 mm/100 km | |||

| Operating distance: 100 km~300 km |

| Bare Foam Pig | LCQZ-RTN | 1. Soft texture and good flexibility. | Starting pressure: 0.02 MPa |

| 2. With strong water absorption, the deformation amount can reach 60%. | Density: 35 kg/m³~220 kg/m³ | ||

| 3. Used for dewatering, cleaning, and drying pipelines. | Withstand pressure: 7 MPa | ||

| Stretch rate: 320% | |||

| Compression ratio: 60 | |||

| Flex life: 50,000 times | |||

| Attrition rate: 4 mm/100 km | |||

| Operating distance: 50 km~150 km | |||

| Operating temperature: -30℃~100℃ |

FAQs About Pipeline Cleaning Pigs

1. What is a pipeline cleaning pig?

A pipeline cleaning pig is a tool used to clean, inspect, and maintain pipelines by traveling through the line.

2. How does a pipeline cleaning pig work?

It travels inside the pipeline, using physical force, brushes, or jets to remove debris and buildup.

3. What types of pipeline cleaning pigs are there?

There are foam pigs, steel mandrel pigs, solid cast pigs, and specialty pigs designed for specific cleaning tasks.

4. How often should you use a cleaning pig in a pipeline?

The frequency depends on the type of pipeline and the nature of the transported material; it could range from monthly to annually.

5. Can pipeline cleaning pigs detect and fix leaks?

Cleaning pigs primarily clean and inspect; they do not repair leaks but can help identify areas where leaks might occur.

Urethane Pigs

Urethane Pigs

Reviews

There are no reviews yet.