Description

I. Introduction to Pig Signal Indicator

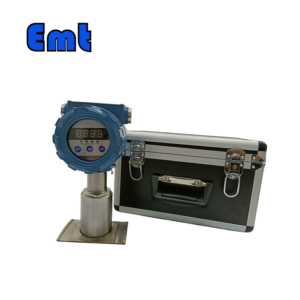

A. What is a Pig Signal Indicator?

Pig signal indicators are devices that detect the presence of a “pig” in pipelines. These tools confirm the pig’s passage at specific points. They provide essential feedback to operators, ensuring that the pigging operation proceeds as planned. This technology allows for real-time monitoring, which is crucial in maintaining pipeline efficiency and safety.

B. The Role of Pig Signal Indicators in Pipeline Maintenance

Pig signal indicators play a vital role in routine pipeline maintenance. They help ensure the cleaning and inspection pigs have passed through the intended sections of the pipeline. This verification is critical to prevent blockages and to maintain the flow of materials. By confirming the pig’s location, these indicators help avoid costly shutdowns and potential accidents. They are instrumental in scheduling maintenance and ensuring that all operations adhere to safety standards.

C. Overview of the Types of Pigging Used in Pipelines

Pipelines use various types of pigging operations tailored to specific maintenance needs. Cleaning pigs are common and remove deposits and debris to prevent corrosion. Inspection pigs, or “smart pigs,” use sensors to gather data about the pipeline’s condition. This data can show wall thickness, corrosion levels, and other critical safety information. Another type involves sealing pigs, which isolate sections for repairs or maintenance. Each pigging type serves a distinct purpose, enhancing the pipeline’s operational integrity and longevity.

Pig Signal Indicator Selection Model

| Configuration parameter | |||

| ●standard configuration | ○Optional configuration | — No | |

| Trigger type(b-bidirectional /f-bidirectional feather /u-u-unidirectional) | ○/○/● | ||

| Flag trigger interagency interaction (No / Yes, the flexibility of the trigger mechanism can be checked online) | —/● | —/● | —/— |

| Wetted part material (316L SS/DSS/INCONEL) | ●/○/○ | ||

| Flange/welding base material(PTFE Coated) A105N/304SS/316LSS/DSS/INCONEL/According to customers’ needs) | ●/○/○/○/○/○ | ||

| Liquid level position in the machine (high _ requires heat tracing / low _ does not require heat tracing) | —/● | ||

| Output junction box(aluminum alloy /316ss) | —/— | ●/○ | ●/○ |

| Output switch (DPDT/SPDT) | —/— | ○/● | ○/● |

| Switching capacity (DC24V 3A/DC24V 5A) | —/— | ●/○ | ●/— |

| Output interface size (M20 × 1.5(F)/1/2″NPT(F)) | —/— | ●/○ | ●/— |

| Pressurized handling tools(2 full thread studs / synchronous special tools) | ●/○ | ||

| Insertion depth adjustment range (±10mm) | ● | ||

Parameters

| Name | Pig Indicator |

| Connection | 2” Welded Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01-75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

| Name | Removable Pig Indicator |

| Connection | 2” Welded Base, NPT Connection |

| Plug body length | 200mm |

| Operating temperature | -20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | Yes |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 20mm |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Base/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

Types of Pig Signal Indicators

A. Mechanical Pig Signals

Mechanical pig signals are the traditional choice for detecting pigs in pipelines. They operate mechanically, triggering a flag or wheel when a pig passes. This simple yet reliable method provides clear visual confirmation. Operators often prefer mechanical signals for their straightforward design and ease of use. These indicators require direct contact with the pig, ensuring accurate detection every time.

B. Non-Intrusive Pig Signals

Non-intrusive pig signals represent a more advanced approach. They detect pigs without any physical contact. These devices use magnetic, ultrasonic, or acoustic sensors to sense the pig’s passage. This method minimizes the risk of mechanical failures and does not interrupt the pipeline’s integrity. Non-intrusive signals are ideal for pipelines carrying sensitive or hazardous materials. They also allow for remote monitoring, enhancing operational safety and efficiency.

Non Intrusive Pig Signaller

Non Intrusive Pig Signaller

Reviews

There are no reviews yet.