Description

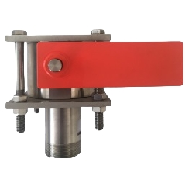

Choose from our EMT pig passage indicators. Our popular intrusive signaler series uses a trigger intrusion into the pipe bore. Additionally, our non-intrusive, magnetic-type pig detectors confirm the passage of pigs carrying magnets. Not sure which option suits your needs? Contact our team today for more information or a quote!

Parameters of Pig Passage Indicator

| Type: Intrusive |

| Connection type: Flange connection |

| Indicator feature: Manual reset flag combined with electrical signals (Manual reset flag and Date and time display combined with electrical signals can also be made) |

| Installing type: 2” Flange. As per ASME B16.5(CLASS150-2500) |

| Plug body length: 200mm/Meet the actual needs |

| Insert depth adjustment: 20mm |

| Operating temperature: -20~120℃/Meet customer requirements |

| NACE MR 0175: Yes |

| Ingress protection: IP66 |

| Explosion-proof class: Exd II BT4 |

| Remove under pressure: No |

| Trigger type: Bi-directional (Uni-directional trigger can also be made) |

| Internal part material: PTFE Coated A105N is standard configuration (304SS/316LSS/DSS/INCONEL/As per MR can meet customer needs) |

| Junction box material: Aluminium alloy/316SS |

| Switch type: DPDT/2*SPDT |

| Switch rating: DC24V 3A/DC24V 5A |

| Configuration parameter | |||

| ●standard configuration | ○Optional configuration | — No | |

| Trigger type(b-bidirectional /f-bidirectional feather /u-u-unidirectional) | ○/○/● | ||

| Flag trigger interagency interaction (no / Yes _ the flexibility of the trigger mechanism can be checked online) | —/● | —/● | —/— |

| Wetted part material(316L SS/DSS/INCONEL) | ●/○/○ | ||

| Flange/welding base material(PTFE Coated A105N/304SS/316LSS/DSS/INCONEL/According to customers’ needs) | ● /○/○/○/○/○ | ||

| Liquid level position in the machine (high _ requires heat tracing / low _ does not require heat tracing) | —/● | ||

| Output junction box(aluminum alloy /316ss) | —/— | ●/○ | ●/○ |

| Output switch (DPDT/SPDT) | —/— | ○/● | ○/● |

| Switching capacity (DC24V 3A/DC24V 5A) | —/— | ●/○ | ●/— |

| Output interface size (M20 × 1.5(F)/1/2″NPT(F)) | —/— | ●/○ | ●/— |

| Pressurized handling tools(2 full thread studs / synchronous special tools) | ●/○ | ||

| Insertion depth adjustment range (±10mm) | ● | ||

Trigger Types

| Indicator Types | ||||

|  |  |  | |

| Indicator Types | A | B | C | D |

| Intrusive Type | Intrusive | Intrusive | Intrusive | Non-intrusive |

| Indicator Features | Popper Type | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals |

Features of Pig Passage Indicator

Our pig passage indicators offer a range of features designed to meet diverse pipeline monitoring needs. The intrusive signaler series utilizes a trigger that intrudes into the pipe bore, providing immediate and reliable confirmation of pig passage. This series is suitable for various pipeline diameters and conditions, ensuring versatility and adaptability in different environments. Additionally, the non-intrusive magnetic-type detectors detect pigs carrying magnets without penetrating the pipeline. This feature minimizes the risk of contamination or damage, making it ideal for pipelines where intrusive methods are not feasible.

Both types of pig passage indicators are built with robust materials to withstand harsh pipeline environments. They are resistant to corrosion, high pressure, and extreme temperatures, ensuring long-lasting performance with minimal maintenance. The indicators offer clear visual or audible signals, making them user-friendly and easy to operate. With high detection accuracy, these devices reduce the risk of missed pig passages or false alarms, enhancing overall pipeline monitoring and maintenance efficiency. Whether you need permanent or temporary installation, our pig passage indicators provide reliable and efficient solutions for your pipeline management.

Weld Connection and Flange Connection

A weld connection joins pipes by melting and fusing their ends. This creates a permanent bond. Welded joints provide high strength and leak resistance. However, they require skilled labor and specialized equipment. Additionally, inspection and maintenance can be challenging.

In contrast, a flange connection uses flanges and bolts to join pipes. This allows for easy assembly and disassembly. Flanged joints simplify maintenance and inspection. They also accommodate alignment adjustments. However, flanged connections might be less strong and leak-resistant than welded joints. Choose the connection type based on your specific needs and conditions.

Pipe Pigs For Pipeline Maintenance

Pipe Pigs For Pipeline Maintenance

Reviews

There are no reviews yet.