Description

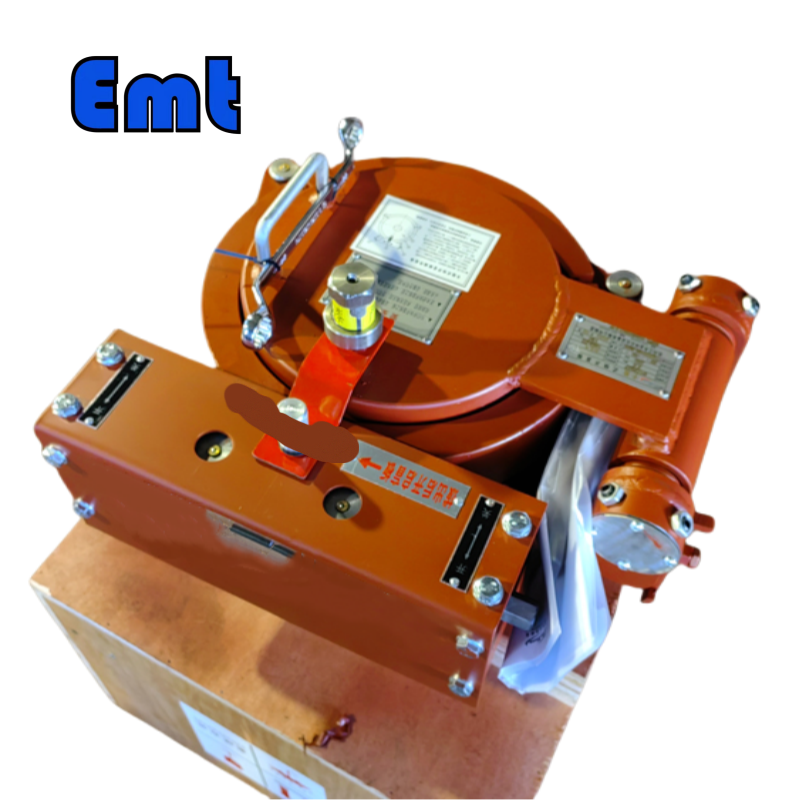

EMT Pig Launcher Closure is a highly engineered component of pipeline maintenance systems, designed to facilitate the safe and efficient insertion and retrieval of pipeline inspection gauges, known as pigs. This closure system features a robust and easy-to-operate mechanism that ensures a secure seal and quick access. It is crucial for minimizing downtime and enhancing productivity in pipeline operations. Particularly suited for oil, gas, and petrochemical industries, the EMT Pig Launcher Closure stands out for its durability and reliability, making it an indispensable tool for routine pipeline maintenance and inspection tasks.

Key Features and Benefits

Below is a detailed examination of its key features and benefits:

1. Enhanced Operational Efficiency

EMT Pig Launcher Closure

The EMT Pig Launcher Closure is a standout feature of the EMT Welded Connection Pig Signaler. Its integral scalable locking ring structure simplifies the operation, enabling a single operator to open and close the pig launcher in less than one minute with minimal effort, requiring less than 200N of force. This rapid operation is crucial for reducing downtime in critical pipeline operations, thereby enhancing overall productivity. The system’s design focuses on user-friendliness and efficiency, easing the workload and speeding up maintenance processes which are often time-sensitive.

Labor and Time Savings

This quick-operating system not only speeds up the process but also significantly reduces labor costs. The ease of operation means that less skilled labor is required, and the quick turnaround times can lead to substantial savings in operational budgets, particularly in high-throughput industrial environments. The reduction in required manpower and the minimal physical effort needed also decrease the risk of operator fatigue and injury. Which contributes to safer workplace conditions. Moreover, by enabling faster operations, the system allows companies to handle more tasks within the same time frame, effectively increasing the throughput of maintenance and inspection operations.

Streamlined Operations and Increased Productivity

The design of the EMT Pig Launcher Closure allows for seamless integration into existing pipeline systems, minimizing the need for extensive retraining or adjustments in operational protocols. Its reliability and ease of operation mean that routine inspections and maintenance can be performed more frequently and with less disruption to overall operations. This consistency in maintenance helps prevent long-term pipeline issues, which can be costly and disruptive to fix. Overall, the system not only saves time and labor costs but also improves the operational lifecycle of the pipeline infrastructure, ensuring that it operates at peak efficiency with reduced risk of downtime due to unforeseen failures.

2. Advanced Sealing Mechanism

Self-Tightening Lip Seal Structure

The unique self-tightening type lip seal structure employed in the EMT Welded Connection Pig Signaler offers an exceptionally tight and reliable sealing mechanism. This advanced design automatically adjusts to maintain a seal under varying pressures and temperatures. Which is critical in maintaining the integrity of the pipeline system. Such adaptability prevents leaks that can lead to significant environmental hazards and costly downtime for repairs, ensuring continuous and safe operation.

Enhanced Safety and Environmental Protection

The robust sealing capability of the self-tightening lip seal is specifically designed to prevent any form of leakage or spillage. Which is paramount in industries handling hazardous or environmentally sensitive materials. By providing a reliable seal, the system significantly mitigates the risk of contamination to the surrounding environment. This is crucial in maintaining compliance with environmental regulations and in achieving sustainability goals. As even minor leaks can have severe consequences for local ecosystems and can result in hefty fines and remediation costs.

Longevity and Reduced Maintenance Costs

In addition to its primary function of preventing leaks, the self-tightening lip seal is also designed for durability. Its ability to adjust to changes in pressure and temperature reduces wear and tear, extending the lifespan of the seal and, by extension, the pipeline system. This durability translates into lower maintenance costs over time, as the need for frequent replacements and repairs is significantly diminished. The reliable performance of the seal minimizes unexpected operational interruptions, which in industrial settings, can lead to substantial financial losses.

Operational Efficiency and Cost-Effectiveness

The self-tightening feature of the lip seal means it maintains an optimal seal without the need for manual adjustments or recalibrations. Which can be both time-consuming and technically demanding. This set-it-and-forget-it aspect contributes to overall operational efficiency, as operators can focus on other tasks without worrying about the integrity of the seal. Furthermore, by reducing the frequency of leak-related shutdowns and maintenance, the seal structure enhances the cost-effectiveness of pipeline operations, providing a clear return on investment through decreased operational costs and enhanced system reliability.

3. Robust Safety Features

Comprehensive Safety Lock System

The safety lock system with a self-locking function is designed to enhance operational safety significantly. Before any pressurization can occur, this system ensures that all locking structures are properly engaged. Moreover, it guarantees complete pressure relief within the container before the blind flange cover can be opened—effectively implementing a fail-safe mechanism that prevents accidents due to premature or incorrect operation.

Secondary Pressure Relief

This feature is particularly important as it provides a built-in redundancy for pressure relief. It ensuring that even if the primary pressure control systems fail. There is an additional layer of safety to protect the equipment and operators.

4. Durable and Versatile Design

Wide Range of Applications

The horizontal design of the Pig Launcher is versatile and can be used with a variety of work mediums, including oil, natural gas, water, and ore pulp. This capability makes it suitable for a broad spectrum of industries, from petroleum refining to mineral processing.

High-Pressure and Corrosion Resistance

The Pig Launcher is engineered to handle pressures ranging from 1.6MPa to 30MPa and includes a corrosion allowance of 2mm. This robust design ensures that the launcher can withstand harsh operational conditions. Including highly corrosive environments typical in oil and gas extraction and processing.

Seismic Fortification

Designed to endure seismic activities with a fortification intensity of up to 7 degrees, the launcher remains stable and operational even in geologically active areas. This resilience is critical for maintaining continuous operations in regions prone to earthquakes.

Quick Opening Closure Different Types

Quick Opening Closure Different Types  Quick Opening Closure

Quick Opening Closure

Reviews

There are no reviews yet.