Description

Introduction

Importance of Pig Detectors in Pipeline Maintenance

A pig detector is a vital tool in the pigging process. Pig detectors track the pig’s location as it traverses the pipeline. Accurate pig detection helps prevent potential blockages and mechanical failures. Timely data from these detectors enables operators to make informed decisions on pipeline integrity and maintenance schedules. Thus, pig detectors enhance safety and operational efficiency in pipeline systems.

Overview of Pipeline Pigging

Pipeline pigging plays a crucial role in the maintenance and cleaning of pipelines. It involves inserting a tool, known as a ‘pig,’ into the pipeline. The pig travels along the pipeline, propelled by the pressure of the fluid inside. As it moves, it performs essential tasks such as cleaning debris and inspecting the interior surfaces. This process ensures the efficient flow of materials through the pipeline.

Parameters

| Name | 20mm Adjustable Pig Detector |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | —20~120℃/Meet customer requirements |

| NACE MR 01-75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 20mm |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL (as per MR) |

Configuration parameter

| Configuration parameter | |||

| ●standard configuration | ○Optional configuration | — No | |

| Trigger type(b-bidirectional /f-bidirectional feather /u-u-unidirectional) | ○/○/● | ||

| Flag trigger interagency interaction (no / Yes _ the flexibility of the trigger mechanism can be checked online) | —/● | —/● | —/— |

| Wetted part material(316L SS/DSS/INCONEL) | ●/○/○ | ||

| Flange/welding base material(PTFE Coated A105N/304SS/316LSS/DSS/INCONEL/According to customers’ needs) | ● /○/○/○/○/○ | ||

| Liquid level position in the machine (high _ requires heat tracing / low _ does not require heat tracing) | —/● | ||

| Output junction box(aluminum alloy /316ss) | —/— | ●/○ | ●/○ |

| Output switch (DPDT/SPDT) | —/— | ○/● | ○/● |

| Switching capacity (DC24V 3A/DC24V 5A) | —/— | ●/○ | ●/— |

| Output interface size (M20 × 1.5(F)/1/2″NPT(F)) | —/— | ●/○ | ●/— |

| Pressurized handling tools(2 full thread studs / synchronous special tools) | ●/○ | ||

| Insertion depth adjustment range (±10mm) | ● | ||

Understanding Pig Detectors

What is a Pig Detector?

A pig detector is a specialized device that identifies the presence of a pig in a pipeline. It serves two primary functions: detecting the exact location of the pig and verifying its movement through the pipeline system. This ensures operators can monitor the pigging process accurately and intervene if necessary.

Types of Pig Detectors

Intrusive Pig Detectors

Intrusive pig detectors interact directly with the pipeline’s internal environment. Operators install these devices into the pipeline wall. They offer precise readings by being in direct contact with the pig.

Non-intrusive Pig Detectors

Non-intrusive pig detectors operate from outside the pipeline. They detect a pig’s passage without any physical contact or alteration to the pipeline structure. These detectors are ideal for pipelines where maintaining integrity is critical or where internal access is challenging.

Specifications of Non-intrusive Pig Detectors

| Name | Non-intrusive Pig Indicator |

| Operating Temperature | —39.8℃/80℃ |

| Operating Humidity | 41%~83% |

| Sensor Type | Magnetic Induction |

| Signal Switch Type | SPDT |

| Passing time | ±2s |

| Cleaning Pig Speed Range | 0.2-10 m/s |

| Switch Capacity | 2A |

| Reset Type | Auto Rese |

| Cable Joint Type | M20*1.5、 1/2NPT F |

| Explosion-Proof | Exd IICT6 Gb |

| IP Grade | IP65 |

Types of Indicators

| Indicator Types | ||||

|  |  |  | |

| Indicator Types | A | B | C | D |

| Intrusive Type | Intrusive | Intrusive | Intrusive | Non-intrusive |

| Indicator Features | Popper Type | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals |

The Role of Pig Detectors in Pipeline Maintenance

Preventing Pipeline Blockages

Pig detectors play a crucial role in preventing pipeline blockages. By tracking the pig’s location, these detectors alert operators to any unusual stops or slow movements that might indicate a blockage. Operators can then take immediate action to address potential issues, ensuring that the pipeline remains clear and functional. This proactive approach minimizes downtime and maintains the flow of materials.

Monitoring for Wear and Corrosion

Pig detectors also assist in monitoring pipeline integrity by detecting signs of wear and corrosion. As the pig travels through the pipeline, detectors can identify variations in its movement or speed that may suggest internal damage or erosion. Such timely detection allows for early maintenance work, preventing more severe damage that could lead to costly repairs or hazardous leaks.

Enhancing Pipeline Efficiency

Regular use of pig detectors contributes significantly to optimal pipeline operations. By ensuring that pigs complete their journey smoothly and efficiently, these detectors help maintain the cleanliness and integrity of the pipeline. Clean pipelines mean less resistance to flow, improving overall efficiency. Additionally, consistent monitoring helps schedule maintenance more effectively, reducing unexpected breakdowns and ensuring continuous operation.

Conclusion

Pig detectors are essential tools that ensure the safety, efficiency, and reliability of pipeline operations. They provide crucial data that helps prevent blockages and monitor for any signs of wear or corrosion. With accurate and timely information, operators can maintain pipelines in optimal condition, reducing the risk of unexpected failures and expensive repairs.

To stay ahead in the rapidly evolving pipeline industry, adopting and upgrading pig detection technology is crucial. Advanced detectors offer greater accuracy and reliability, empowering companies to enhance their operational efficiency and safety standards. Investing in the latest pig detection technologies is a proactive step toward sustainable pipeline management.

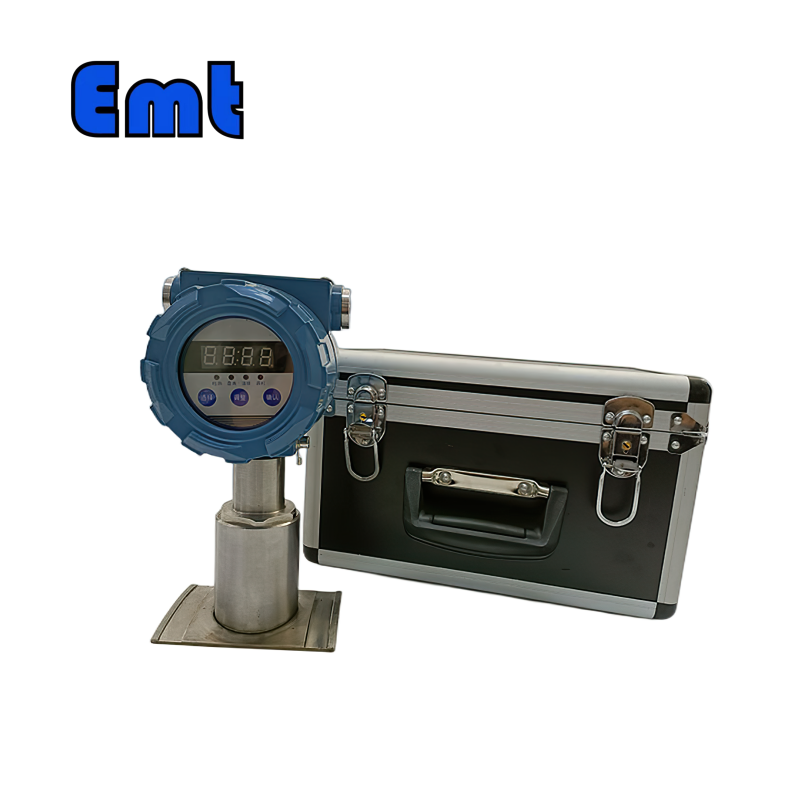

EMT Pig Signaller With A Ball Valve

EMT Pig Signaller With A Ball Valve

Reviews

There are no reviews yet.