Description

What Is Oilfield Pigging?

Oilfield Pigging is the key link of pipeline maintenance and operation. It involves inserting a device called a pig into a pipe. The pig runs through the pipe and cleans and inspects the pipe. This process helps maintain the efficiency and integrity of the pipeline. The pig removes debris to prevent clogging and flow restriction. In addition, they help detect problems such as corrosion and leakage. Different types of pigs have different uses, such as cleaning, inspecting, or maintaining pipes. Regular pigging ensures optimal performance and extends the life of the pipe. Therefore, pigging is essential in industries such as oil and gas, water treatment, and chemical processing.

The Oilfield Pigging Process

Pre-Pigging Preparations

Pipeline Assessment

Before commencing pigging, the operator must thoroughly evaluate the pipe. This includes checking for problems such as clogging, corrosion, or structural defects. Operators also need to assess the pipeline’s length, diameter, and operating conditions. This assessment helps determine the appropriate pigging strategy and ensures safety during the operation.

Selecting the Right Pig

Choosing the right pig is crucial to the success of the pigging operation. Different pigs have different uses, such as cleaning, inspection or maintenance. Operators consider factors such as debris type, pipe material, and specific job requirements. Choosing the right pig ensures efficient cleaning and accurate data collection.

Executing the Pigging Operation

Step-by-Step Process

At the beginning of the pigging operation, the pig is inserted into the pipe through the starting station. The pig is then pushed through the pipe by product flow or external force. When it moves, the pig performs its assigned function, whether it’s cleaning, inspecting, or both. The process ends when the pig arrives at the receiving station and the operator takes it out for analysis.

Monitoring and Control

Continuous monitoring is essential in pigging operations. The operator uses a tracking system to track the pig’s progress and ensure that the pig moves through the pipeline. Monitoring helps identify any issues in real-time, such as pig stalling or unexpected debris. Effective controls ensure safe and efficient pigging operations with minimal risk and interference.

Post-Pigging Procedures

Data Analysis

After the pig is retrieved, the data collected is analyzed to assess the condition of the pipeline. This analysis includes examining the removed debris, assessing the pig’s performance, and identifying any problems found. Data analytics can provide valuable insights into the health of the pipeline, guiding future maintenance and operational decisions.

Maintenance and Follow-Up Actions

Based on the data analysis, operators plan the necessary maintenance and follow-up actions. This may include additional cleaning, repair, or preventive measures to address the identified problem. Regular maintenance ensures that pipes are kept in top condition, prevents costly failures, and extends their service life. Consistent follow-up over time maintains the integrity and efficiency of the pipeline.

Types of Pigs Used in Oilfield Pigging

Foam Pigs

Characteristics and Uses

Foam pigs, made from open-cell polyurethane foam, are versatile and lightweight. They adapt to various pipeline diameters and configurations, making them ideal for cleaning and dewatering. Foam pigs effectively remove soft debris, liquids, and light deposits, ensuring smooth pipeline operations.

Advantages and Limitations

Foam pigs offer several advantages, including high flexibility and low cost. They can navigate through tight bends and complex pipeline geometries. However, foam pigs have limitations. They may not effectively remove hard deposits or handle high-pressure environments. Their durability is also lower compared to other pig types.

Mechanical Pigs

Cleaning Pig with Cups

A cleaning pig with cups features flexible cups that effectively scrape the pipeline walls. These cups can adapt to various pipeline diameters, ensuring thorough cleaning. This type of pig excels at removing medium to heavy deposits, such as sludge and wax. Additionally, the cups create a seal, enhancing the pig’s ability to push debris through the pipeline. Operators often use cleaning pigs with cups in routine maintenance to maintain optimal flow. Their versatility makes them suitable for both new and old pipelines.

Cleaning Pig with Discs

A cleaning pig with discs uses rigid discs to provide a powerful scraping action. These discs are designed to tackle tougher debris, including scale and hardened deposits. The rigid structure ensures consistent contact with the pipeline walls, maximizing cleaning efficiency. Cleaning pigs with discs is ideal for pipelines with severe fouling. They are especially useful in preparation for the inspection of pigs, ensuring the pipeline is free of obstructions. Their robust design makes them a reliable choice for demanding cleaning tasks, and maintaining pipeline integrity.

Applications

Mechanical pigs are used for more rigorous cleaning tasks. They remove hard deposits, scale, and other stubborn contaminants. These pigs are often deployed in pipelines with severe fouling or in preparation for inspection pigs. They ensure the pipeline is thoroughly cleaned and free of obstructions.

Polyurethane Pigs

Features

Polyurethane pigs are made from durable polyurethane material. They come in various configurations, including solid-body and modular designs. These pigs offer high resistance to wear and abrasion, making them suitable for challenging environments. They can be used for cleaning, batching, and gauging applications.

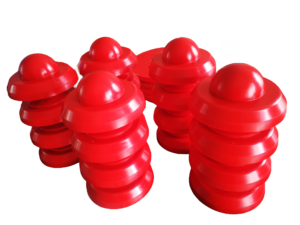

Cleaning Ball Pigs

Specific Use Cases

Cleaning ball pigs, typically spherical in shape, are used in specific scenarios. They are effective for removing soft deposits and liquids in pipelines with limited access points. These pigs are often used in pipelines with small diameters or in systems where traditional pigs cannot navigate. Cleaning ball pigs ensure efficient cleaning with minimal disruption.

Pipeline Cleaning Pigs

Pipeline Cleaning Pigs

Reviews

There are no reviews yet.