Description

What Is Non-intrusive Pig Signaler?

1. The Non-intrusive Pig Signaler product complies with the relevant provisions in the SN2-TQZ explosion-proof Pig indicator enterprise standards.

2. The unprocessed inner surface is coated with arc-resistant paint, and the outer surface is sprayed with plastic.

3. The minimum clearance in the wiring cavity is≥3nm, and the minimum creepage distance is≥3mm.

4. NO OPEN WITH ELECTRICITY;

5. CT6 Gb

6. After assembly, this product should be able to withstand AC 50Hz voltage and 500V duration 1min power frequency withstand voltage test.

7. The explosion-proof surface shall not be scratched, bumped, or coated with 204-1 anti-rust oil during assembly.

8. All fasteners must have an anti-loosening device and be installed firmly; The tightening torque of flameproof threads should not be less than 20Nm.

Parameters of Non-intrusive Pig Signaler

| Name | Non-intrusive Pig Indicator |

| Operating Temperature | —39.8℃/80℃ |

| Operating Humidity | 41%~83% |

| Sensor Type | Magnetic Induction |

| Signal Switch Type | SPDT |

| Passing time | ±2s |

| Cleaning Pig Speed Range | 0.2-10 m/s |

| Switch Capacity | 2A |

| Reset Type | Auto Rese |

| Cable Joint Type | M20*1.5、 1/2NPT F |

| Explosion-Proof | Exd IICT6 Gb |

| IP Grade | IP65 |

Working Process

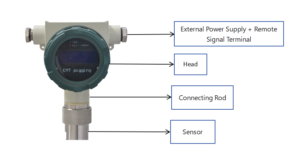

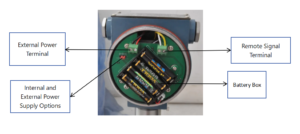

The Non-intrusive Pig Signaler device uses a magnetic detection principle to detect, send signals, and record the passage of the pig at key points in the pipeline. EMT Non-intrusive Pig Signaler devices can be used in onshore and offshore installations.

Applications of Non-intrusive Pig Signaler

Monitoring Pipeline Pigs

Non-intrusive pig signalers monitor the passage of pipeline pigs. They detect pigs without interrupting the pipeline flow. This feature ensures continuous operation during pigging activities. Operators use these signalers to track pig location and progress. Accurate monitoring helps in scheduling maintenance and cleaning tasks.

Ensuring Pipeline Integrity

Non-intrusive pig signalers play a key role in ensuring pipeline integrity. They detect anomalies in pig movement, indicating potential issues. These signalers help identify blockages, leaks, and other problems. Early detection allows for timely intervention, preventing major pipeline failures. This proactive approach enhances pipeline safety and reliability.

Enhancing Operational Efficiency

Non-intrusive pig signalers enhance operational efficiency. They provide real-time data on pigging activities. This information helps optimize pipeline maintenance schedules. Operators can reduce downtime by planning interventions based on accurate data. Efficient maintenance leads to cost savings and improved pipeline performance.

Environmental Monitoring

Non-intrusive pig signalers contribute to environmental monitoring. They ensure the efficient operation of pipelines transporting hazardous materials. Accurate pig tracking helps prevent leaks and spills. This reduces environmental risks associated with pipeline operations. Signalers play a crucial role in maintaining regulatory compliance.

Supporting Diverse Industries

Non-intrusive pig signalers support various industries. Oil and gas, chemical, and water treatment sectors benefit from their use. These signalers improve pipeline management across different applications. Their versatility makes them essential in both industrial and municipal settings. By enhancing pipeline monitoring, they support overall operational excellence.

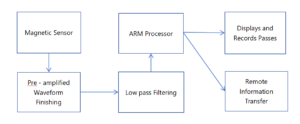

Detecting Principle

The EMT Non-intrusive Pig Signaler incorporates a magnetic sensor that detects changes in the magnetic field (Gauss level). Consequently, operators must use the EMT Non-intrusive Pig Signaler device in conjunction with pigs fitted with rare earth magnets (neodymium iron boron) around the pig body. The device detects pigs at speeds ranging from 0.1 to more than 10 m/s.

![]()

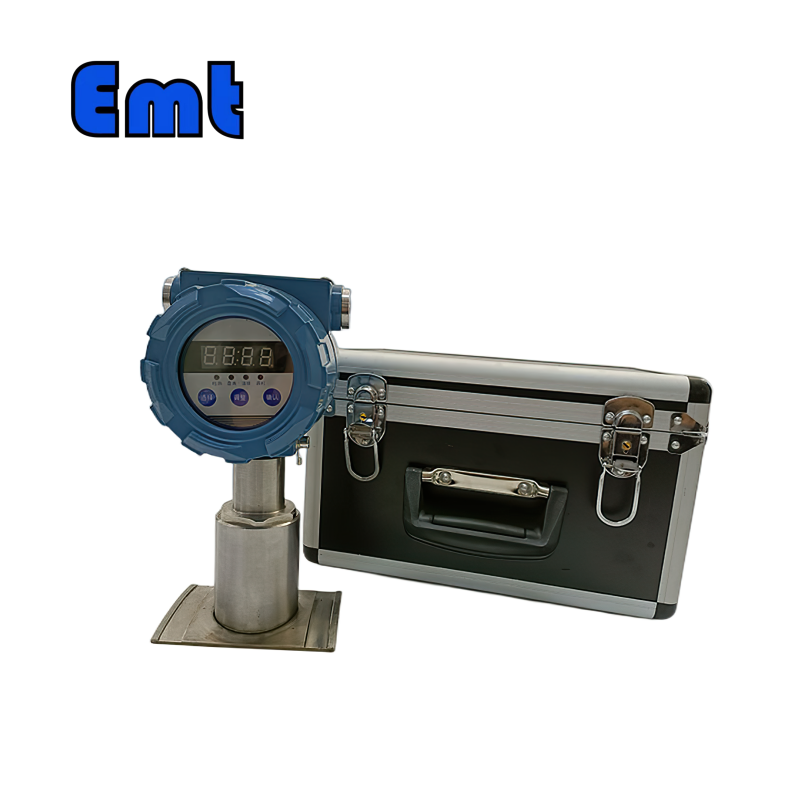

Pig Signal Detector

Pig Signal Detector

Reviews

There are no reviews yet.