Description

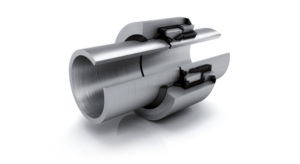

Introducing the Monolithic Insulation Joints, an advanced solution designed for the most challenging underwater and marine environments. This robust joint is specifically engineered for ultra-deep wading areas. Therefore, it’s an ideal choice for underwater and marine oil and gas exploration and transportation pipelines.

- Waterproof Depth: Engineered to withstand depths ranging from 100 to 1000 meters, ensuring reliable performance under extreme pressure conditions. For applications requiring even greater depth capabilities, we offer on-demand customization for operations exceeding 1000 meters.

- Applications: This insulating joint is perfectly suited for high-demand scenarios where exposure to deep water is a constant challenge. Its superior design and materials ensure optimal functioning in ultra-deepwater regions, providing uninterrupted service in the extraction and transportation of oil and gas.

By integrating cutting-edge technology and materials, the Super Waterproof Insulating Joint secures the integrity and efficiency of pipeline systems in some of the most demanding aquatic environments around the globe.

Technical Specifications of Monolithic Insulation Joints

Technical performance | |

| Operating pressure: | design pressure 1.6 ~ 42MPa |

| Operating temperature: | design temperature -40 ~ +300 ℃ |

| Resistance: | greater than 10M at 2.5KV DC |

| Insulation strength: | 30s no breakdown at 50Hz 3KV,AC |

| It has reached the international advanced level | |

Insulating Joint Upgrade I | ||

| Before upgrade | After upgrade | |

| Reinforced waterproof insulating joints | Super waterproof insulating joint | |

| Features | Suitable for wet soil and flooded areas | Suitable for: ultra-deep wading area |

| Waterproof depth < 5 meters | Waterproof depth: 100–1000 meters (more than 1000 meters on-demand customization) | |

Monolithic Insulation Joints Upgrade II-High Torque Type

Introducing the Insulating Joint Upgrade II – High Torque Type, a revolutionary advancement in pipeline technology. This joint features a unique meshing seal structure that delivers superior anti-torque performance compared to traditional insulating joints. Its design torque exceeds 70% of the piping’s yield strength, matching the designed bending moment and tripling the EU standard.

Ideal for regions prone to geological instability, such as areas with frequent settlements, landslides, earthquakes, and volcanic activity, this high torque resistant joint enhances pipeline resilience. It effectively combats the abnormal torque generated during geological events, ensuring continuous safety and reliability in pipeline transportation.

With its world-leading design, the High Torque Type Insulating Joint not only strengthens the pipeline’s weakest link but also significantly boosts its ability to withstand geological disasters. This makes it an essential component for maintaining operational integrity in high-risk environments.

Features

The pressure grade of Monolithic Insulation Joints ranges from PN1.6 to PN42 MPa. Material of the product includes carbon steel, low alloy steel, stainless steel and duplex stainless steel, non-ferrous metals, and metal composite materials three series of more than 30 varieties. The operating temperature of it is -40℃~ +240℃. Suitable for all kinds of oil, gas, and chemical media, it can be used on the ground, overhead, and underwater. Our Monolithic Insulation Joints are permanently maintenance-free. Besides, they meet the requirements of all known engineering projects. Our products can meet the domestic and foreign insulation joint standards and requirements. We have a perfect quality control system, which meets a variety of strict insulation joint testing.

The characteristics and level of our technology

- Monolithic Insulation Joint seals typically come in two types: “O” and “U” rings. The ZJ3 model uses an “O” ring, which offers several benefits due to its simple production process and cost-effectiveness. Unlike the traditional “O” ring, which features a classic static seal groove in almost all China Petroleum drawings, the ZJ3’s “O” ring has a unique trapezoidal shape with one straight side and one sloped side. When under pressure, this design tightens the seal along the slope, enhancing the O ring’s ability to utilize its elastic modulus effectively. This structure blocks minor gaps that could lead to leaks, ensuring high reliability even when the system faces stress-induced instability. Over 20 years, our insulation joints have continually improved, yet the original seal ring design remains unchanged without any structural leakage failures.

- In this series, we feature a high-temperature insulating joint designed for temperatures up to 300℃, typically operating long-term at 240℃. This joint is ideal for steam, thermal oil, and other high-temperature mediums. Our research and development team has leveraged cutting-edge materials from China’s military and aerospace sectors, integrating polyimide composite and bisphenol A modified silicone into the production process. Polyimide (PI), a novel polymer produced in China, boasts exceptional performance characteristics. It has proven its worth in major projects like Shenzhou and the Chang’e, demonstrating the ability to withstand temperatures as high as 600℃, operate long-term at 333℃, and maintain integrity at temperatures as low as -269℃ without brittleness. PI’s introduction has fundamentally enhanced our insulating joints’ temperature resistance, enabling us to surpass the traditional temperature range of -20℃ to +80℃ and achieve -40℃ to +240℃ capabilities. This breakthrough has earned the product a Chinese patent (Patent No.: ZL200820074213.9).

Conclusion

In conclusion, our Monolithic Insulation Joints set the industry standard with unmatched performance in extreme environments. From deep-sea applications to high-torque, geologically unstable regions, our joints ensure the highest levels of durability and reliability, supporting the critical infrastructure of oil, gas, and chemical industries worldwide.

Monolithic Insulation Joint

Monolithic Insulation Joint

Reviews

There are no reviews yet.