Description

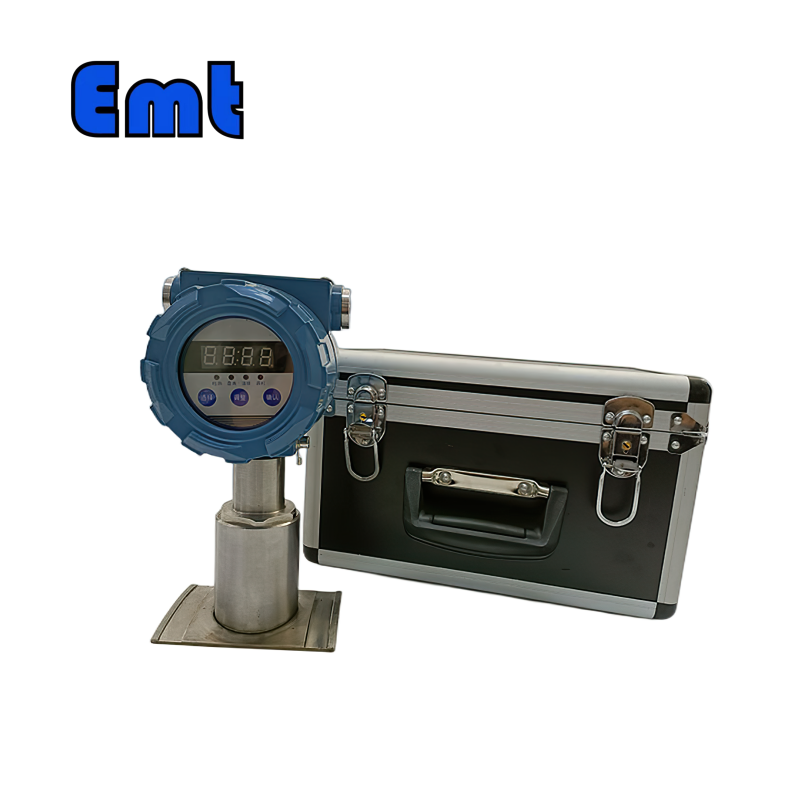

The EMT Magnetic Pig Signaller is a sophisticated device designed to detect the passage of pigs within pipelines. It is crucial for maintenance and monitoring in industries such as oil and gas, energy, mining, and construction. This pig signaller is particularly suited for operations that require high reliability under tough conditions, thanks to its robust construction and advanced features.

Technical Specifications:

- Material Options:

- Stainless Steel 304

- Stainless Steel 316

- Duplex Stainless Steel (DSS) F51

- Carbon Steel A105N

- Inconel 625

- Operating Temperature Range: -20°C to +120°C

- Design Pressure: ANSI up to 2500#/API 10000 Psi

- Trigger Types:

- Bi-directional

- Bi-directional Feather

- Uni-directional

- Indicator Types:

- Manual reset flag

- Manual reset flag combined with electrical switch output

- Digital display combined with electrical switch output

- Mounting Options:

- 2″ flange connection

- 2″ welded nipple

- 2″ welded base- NPT nipple connection

- Adjustability Range: 0-14mm

- Weight: 5 kg

- Package Size: 45 x 35 x 20 cm

- Gross Weight: 6 kg

1. Key Specifications and Features of the EMT Magnetic Pig Signaller:

- Type. Pig Signaller, suitable for intrusive applications.

- Material Construction. Available in a variety of durable materials including Stainless Steel 304, Stainless Steel 316. Duplex Stainless Steel F51, Carbon Steel A105N, and Inconel 625. Which are known for their high corrosion resistance and strength.

- Operating Temperature. Can operate effectively within a range from -20℃ to +120℃, making it adaptable to various environmental conditions.

- Design Pressure. Capable of handling pressures up to ANSI 2500#/API 10000 Psi, ensuring performance under high-pressure scenarios.

- Trigger Types. Offers flexibility with three trigger options; Bi-directional, Bi-directional Feather, and Uni-directional, catering to different operational needs.

- Indicator Types. Available with a manual reset flag, a manual reset flag combined with an electrical switch output, or a digital display combined with an electrical switch output, providing clear and versatile signaling options.

- Mounting Types.: Includes three mounting options – 2″ flange connection, 2″ welded nipple, and 2″ welded base- NPT nipple connection. Which facilitate easy installation and compatibility with various pipeline systems.

- Adjustability. Features an adjustable range of 0-14mm, allowing for precise positioning within the pipeline.

2. Advantages of the EMT Magnetic Pig Signaller:

Durability and Low Maintenance

The EMT Magnetic Pig Signaller is constructed from high-grade materials such as Stainless Steel 304, Stainless Steel 316, Duplex Stainless Steel F51, Carbon Steel A105N, and Inconel 625. These materials are chosen for their exceptional resistance to corrosion and ability to withstand harsh environmental conditions, from extreme temperatures to highly corrosive substances. This durability ensures that the device requires minimal upkeep, reducing the frequency and cost of maintenance. The robust construction also means the signaller can perform reliably over long periods, minimizing the need for replacements and thus contributing to cost savings.

Cost-Effectiveness

Designed with efficiency and longevity in mind, the EMT Magnetic Pig Signaller provides an economical solution for pipeline monitoring. It reduces the overall lifecycle costs associated with pipeline maintenance by decreasing the frequency of pigging failures and the need for frequent system checks. By investing in such a device, operators can avoid costly pipeline blockages or leaks, which can also lead to expensive repairs and operational downtime. So the initial investment in a high-quality pig signaller can lead to significant savings over the life of a pipeline.

High Performance

Because the EMT Magnetic Pig Signaller ensures high wear resistance, which is critical in the abrasive environments often found in pipeline systems. Its excellent cleaning performance ensures that it can effectively signal the passage of pigs. Which works not only for cleaning but also for inspection purposes. The accurate location tracking feature of the signaller is crucial for precisely identifying where interventions may be needed, thus enhancing the efficiency of maintenance operations. So this precise tracking helps in quick response to potential issues, thereby improving the safety of the entire pipeline operation.

3. Application of EMT Pig Signaller

The EMT Magnetic Pig Signaller is an essential device for effective pipeline management, utilized across various industries including oil and gas, energy, mining, and construction. This tool is specifically designed to detect the passage of pipeline pigs. Then the devices that are used to perform cleaning and inspection operations within pipelines. Its primary function is to ensure that these maintenance activities are tracked and monitored accurately, facilitating timely interventions and maintenance.

Constructed to withstand harsh operating conditions, the EMT Magnetic Pig Signaller is built from materials like Stainless Steel and Inconel. Which provide resistance to corrosion and extreme temperatures. This durability is crucial for operations in environments that can degrade lesser materials, ensuring the signaller’s longevity and reducing the frequency of replacements.

The device comes with adjustable features and multiple mounting options. Which makes it compatible with a wide range of pipeline specifications. It also can handle high pressures and is designed for easy installation, adding to its operational efficiency. Its high wear resistance and excellent cleaning performance are critical for maintaining the integrity of the pipeline by ensuring that the pigs effectively remove debris and residues that could potentially cause blockages or corrosion.

Moreover, the EMT Magnetic Pig Signaller’s accurate location tracking is a standout feature. It also enhances safety by precisely identifying where pigs have traveled within the pipeline system. So this capability allows for targeted maintenance checks, reducing the likelihood of leaks and ruptures that can lead to environmental damage and costly operational downtime.

EMT Pig Signaller-2'' Welded Base, NPT Connection

EMT Pig Signaller-2'' Welded Base, NPT Connection  Foam Pigs Pipeline Cleaning

Foam Pigs Pipeline Cleaning  Oil Pipe Pig

Oil Pipe Pig  EMT Intrusive Type Pig Signaller

EMT Intrusive Type Pig Signaller

Reviews

There are no reviews yet.