Description

The EMT-SI Injection Quills are essential components designed for use in chemical injection applications within pipelines. These devices facilitate accurate and efficient delivery of chemicals into a pipeline system, essential for maintenance and monitoring operations. Here is a detailed summary of the key attributes and specifications of the EMT-SI Injection Quills:

1. Key Attributes

- Place of Origin: Liaoning, China

- Brand Name: Emt

- Customized Support: Offers OEM, ODM, and OBM services, allowing for customization in design and functionality to meet specific client needs.

- Material Options. : Available in various materials including Carbon Steel, Stainless Steel 304, Stainless Steel 316, Duplex Stainless Steel (DSS F51). Carbon Steel A105N, and Inconel 625, to suit different environments and chemical compatibility requirements.

- Size Range: Sizes available from 1/2″ to 4″, with options for customization to fit specific pipeline configurations.

- Pressure Ratings: Designed to handle high-pressure applications, ensuring durability and reliability under stress.

- Certifications: Certified to ISO 9001 standards, ensuring quality and compliance with international regulations.

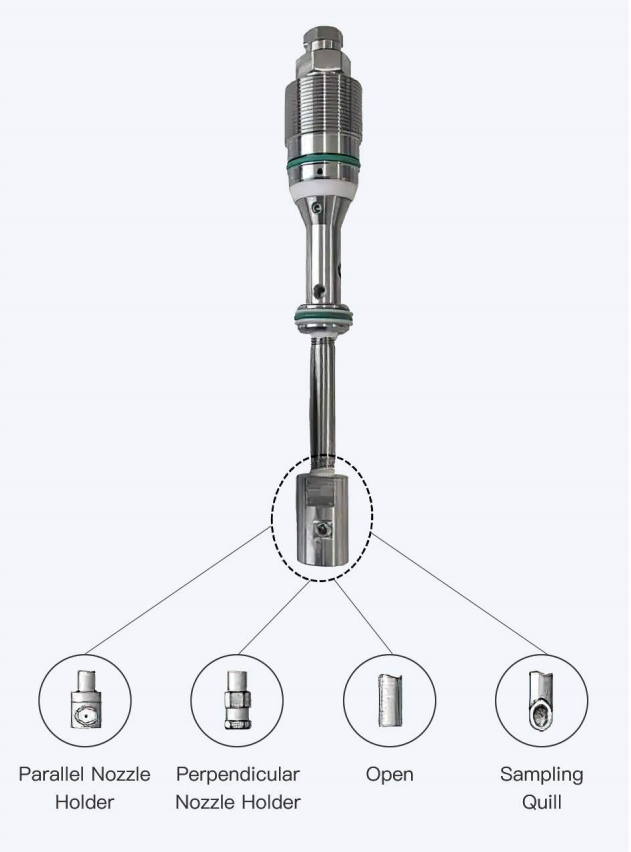

2. Product Composition of EMT-SI Injection Quills

Access Fitting Body

The Access Fitting Body is a crucial component of the EMT-SI Injection Quills, designed to be highly adaptable and secure for varying pipeline requirements:

- Mounting Configurations:

- Weld Mounting. : This option allows for a permanent and robust connection to the pipeline, typically used in applications where long-term stability and security are crucial. The weld mounting ensures that the fitting becomes an integral part of the pipeline system, providing reliable service under extreme conditions.

- Flanged Mounting. Offers flexibility for maintenance and inspection as it allows for easier disassembly and reassembly. This type is preferred in systems where periodic adjustments or inspections are necessary. Flanged connections are easier to deal with in terms of routine maintenance and emergency repairs compared to welded configurations.

- Types of Fitting Bodies:

- No Tee Type. A straightforward design that integrates directly with the pipeline, used in simpler applications where a direct line of injection or monitoring is required without any bypass or additional branching.

- Tee Type. Incorporates a ‘tee’ configuration that allows for branching off, suitable for systems requiring multiple injection points or simultaneous monitoring and injection. So this type provides additional versatility in managing fluid flow within the system.

Access Fitting Plug

The Access Fitting Plug is essential for securing the functional components like corrosion coupons or the injection quills within the Access Fitting Body:

- Connection Security. The plug is designed to ensure a tight and secure fit within the Access Fitting Body, preventing leaks and ensuring that the inserted components (corrosion coupons, chemical injection nuts) are held firmly in place.

- Material Compatibility. Like the body, the plug is made from materials that are selected based on the specific needs of the application. Such as resistance to handle the chemicals, pressure ratings, and environmental conditions.

- Design Features. Typically features threading or other mechanical means to ensure a secure lock within the body, and may include seals like O-rings to prevent any bypass of fluids around the plug.

Protect Cover

- Material Durability. Constructed from materials that are chosen for their strength and resistance to corrosion, impact, and temperature variations. It also ensures that the cover can withstand harsh conditions.

- Design Considerations. The cover is designed to fit snugly over the Access Fitting Body, often equipped with a gasket or seal to prevent the ingress of contaminants such as dirt, debris, and water.

- Operational Safety. In addition to protecting from physical damage, the cover also plays a role in safety by preventing unauthorized access to the components inside, thus avoiding potential tampering or accidental exposure to hazardous substances.

3. Features and Benefits

Ease of Operation

The EMT-SI Injection Quills are engineered for simplicity, making them exceptionally user-friendly. So they feature a design that limits the number of settings and adjustments, allowing operators to manage them without extensive training or technical knowledge. This ease of operation not only enhances user experience but also significantly reduces the chance for human error during setup and use.

High Accuracy and Efficiency

Accuracy in chemical dosing is paramount in pipeline maintenance, and the EMT-SI Injection Quills excel in this aspect. They are calibrated to deliver precise amounts of chemicals, tailored to the specific needs of the pipeline, ensuring that the integrity and performance of the pipeline system are maintained. Then this high level of accuracy prevents the common problems of under or overdosing that can lead to system inefficiencies or damage.

Cost-Effectiveness

The EMT-SI Injection Quills are an economically advantageous solution for pipeline maintenance. They are priced competitively, offering significant cost savings upfront compared to other injection systems. Then the durability of the quills means they are less likely to need replacement or frequent maintenance. Which further reduces the long-term operational costs. Additionally, their design minimizes chemical wastage by ensuring precise dosing. Which not only saves money on chemical costs but also reduces the environmental impact of excess chemicals introduced into the system.

4. Packaging and Delivery

- MOQ. : Available from 1 set, accommodating both large-scale and smaller, specialized applications.

- Packaging: Securely packed in a plywood case to ensure safe transportation.

- Delivery Port: Dalian, China

- Packaging Size and Weight: Each package measures 40X20X60 cm with a gross weight of 3.000 kg per item.

EMT Flanged Injection Quill

EMT Flanged Injection Quill  EMT Sample Quill

EMT Sample Quill

Reviews

There are no reviews yet.