Description

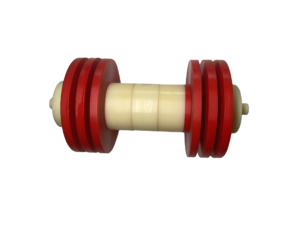

Introduction to ABS Cleaning Pig

EMT ABS Cleaning Pig is one of the EMT pipe cleaning tools. Since our inception in 1993, we have been delivering pipeline equipment and associated services to pipeline industries. The industries include chemical processing, oil and gas, and water treatment. Quality first, reputation first, leading technology, and considerate service are our company principles.

ABS pigs, made from Acrylonitrile Butadiene Styrene, are used in pipeline cleaning and maintenance. They are valued for their lightweight and cost-effective nature. These pigs are suitable for less demanding applications where high durability is not as crucial. ABS pigs are easier to handle and can be effective for basic cleaning tasks. However, they might not be as flexible or abrasion-resistant as polyurethane pigs, making them less ideal for harsh environments or complex pipelines. Over time, substances like oil, gas, or chemicals can leave residue or buildup along the inside walls of a pipeline. ABS Cleaning Pigs can remove this unwanted build-up, ensuring that the pipeline remains clean and functions at its best.

About ABS Material

Acrylonitrile Butadiene Styrene is a thermoplastic polymer material with high strength, good toughness and easy to be machining. Because of its high strength, corrosion resistance and high temperature resistance, it often works in the manufacture of plastic shells for instruments. ABS resin features are high strength, good toughness, easy to process molding thermoplastic polymer material.

ABS plastic has the common properties of three components. A makes it resistant to chemical corrosion, and heat resistance, and has a certain surface hardness. B makes it have high elasticity and toughness. S makes it have the processing and forming characteristics of thermoplastics and improve electrical properties. Therefore, ABS plastic is a kind of “tough, hard and rigid” material with easy access to raw materials, good comprehensive performance, cheap price and wide use. ABS plastics have been widely used in machinery, electrical, textile, automobile, aircraft, ships and other manufacturing industries and chemical industry.

Advantages

ABS is a thermoplastic polymer structural material, also known as ABS resin. The material has high strength, good toughness, and easy processing. ABS has good electrical insulation. Temperature, humidity, and frequency can not affect it. And it also works in most environments.

ABS is the acronym of Acrylonitrile Butadiene Styrene, which refers to acrylonitrile-butadiene styrene copolymer. It is a thermoplastic polymer structural material with high strength, and good toughness. And it is easy to be machined, also known as ABS resin. ABS is a polymer material with good toughness, high strength and easy processing. ABS is a terpolymer of styrene, butadiene, and acrylonitrile. This feature effectively combines the performance of the three materials. Besides, it has the characteristics of corrosion resistance, heat resistance and impact resistance. It is widely used in textile, automobile, ship, machinery and other manufacturing industries and the manufacturing of chemical industry.

ABS is a thermoplastic polymer material, which refers to acrylonitrile-butadiene-styrene copolymer, which has the characteristics of high strength, good toughness, and easy processing and forming. The ABS material behaves normally in the environment of -25℃~60℃, and the surface of the processed product is smooth and clean, mainly used in alloys and plastics.

ABS is the acronym for Acrylonitrile Butadiene Styrene, which refers to acrylonitrile butadiene styrene copolymer. It is a thermoplastic polymer material structure with high strength, good toughness.

Cost of ABS Pigs

The cost of ABS pigs compared to other types of pipeline pigs can be influenced by several factors:

Material Costs: ABS is generally cheaper than more durable materials like polyurethane.

Durability: ABS pigs may have a shorter lifespan, impacting long-term costs.

Application Requirements: Simpler applications may suit ABS pigs, while demanding environments might require more expensive materials.

Customization: The level of customization needed for specific pipeline conditions can affect pricing.

Production Volume: Larger production runs can reduce costs through economies of scale.

EMT Pipe Cleaning Pigs

Besides ABS Cleaning Pig, we also provide many other types of pigs, like mechanical cleaning pigs, solid cast pigs, foam pigs, polly pigs, and so on. We are good manufacturers of products for corrosion monitoring and pipeline cleaning. Since our company’s inception in 1993, we have been delivering pipeline equipment and associated services to pipeline industries, including chemical processing, oil and gas, and water treatment.

Pipeline cleaning pigs maintain and optimize pipeline operations across various industries. In the oil and gas sector, operators use them to remove debris, wax, and scale, ensuring smooth flow and preventing blockages. Water treatment facilities deploy cleaning pigs to clear sediment and biofilm, maintaining water quality and system efficiency. Chemical processing plants utilize them to clean residue and prevent contamination between batches. Additionally, pipelines in food and beverage industries benefit from cleaning pigs to uphold hygiene standards and prevent product cross-contamination. These versatile tools enhance pipeline integrity and operational efficiency by actively managing cleanliness and flow.

Intrusive Pig Signaller

Intrusive Pig Signaller

_032003200_4429.jpg)

Reviews

There are no reviews yet.