Description

Bumper Nose is one of the accessories of pipeline cleaning pigs. Specifically, it is a protective front-end component that is attached to a pipeline pig(a device used to clean, inspect, or maintain pipelines). It is typically made of durable polyurethane or rubber and is designed to:

Protect the pig body and internal components from impact.

Guide the pig through complex pipeline geometries.

Absorb shock when the pig hits obstacles or pipeline features (e.g. valves, bends, reducers).

Sometimes assist in sealing or flow diversion depending on the pig design.

Functions of a Bumper Nose

| Function | Description |

|---|---|

| Shock Absorption | Acts as a cushion when the pig contacts hard surfaces. |

| Impact Protection | Protects the pig body, tracking equipment, or sensors from frontal damage. |

| Guidance | Helps the pig transition smoothly through bends, tees, and welds. |

| Sealing | May contribute to sealing efficiency in some pig designs. |

| Alignment | Ensures the pig stays centered, especially in varying pipeline diameters. |

Common Materials

Bumper Noses are typically made from:

Polyurethane: Offers high wear resistance and flexibility.

Natural or synthetic rubber: Provides excellent impact resistance.

Composite blends: Used for higher strength or chemical resistance.

Applications

Bumper noses are used on various types of pigs, including:

Cup pigs

Disc pigs

Smart pigs (intelligent pigs with sensors or electronics)

They’re especially critical in launch and receive operations, where pigs are more likely to encounter hard surfaces or unexpected obstructions.

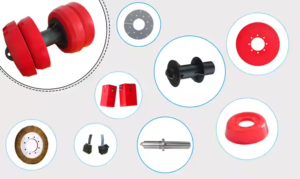

Common Accessories of Pipeline Cleaning Pigs

| Accessory | Function |

|---|---|

| Bumper Nose | Protects the pig from frontal impact and helps guide it through the pipe. |

| Cups | Provide sealing and propulsion using the flow of the product. |

| Discs | Used for scraping and sealing; often in multi-disc configurations. |

| Brushes | Clean the internal pipe wall by removing debris, rust, scale, and wax. |

| Magnets | Collect ferrous debris (rust, scale, welding slag) from the pipeline. |

| Transmitter Cavity | Houses a tracking transmitter (electromagnetic or acoustic). |

| Tracking Transmitter | Emits signals to locate and track the pig’s position in the pipeline. |

| Gauge Plates (Caliper Plates) | Detect internal obstructions or deformations in the pipeline. |

| Rear and Front Guide Discs | Help stabilize the pig and guide it through the pipeline. |

| Sealing Rings / O-Rings | Improve the pig’s ability to maintain a tight seal. |

| Central Mandrel | The core body of the pig to which all components are attached. |

| Bypass Ports | Allow flow through the pig to reduce pressure differential or carry debris. |

| Wear Indicators / Wear Pads | Show the extent of wear for maintenance planning. |

Why Is a Bumper Nose Necessary?

Using a bumper nose on pipeline cleaning pigs offers significant advantages over operating without one. It acts as a shock absorber, protecting the pig from frontal impacts with pipeline features such as valves, welds, or reducers. This added protection helps prevent damage to the pig’s body and critical components like sensors or transmitters, especially in smart pigs. By reducing direct contact with hard surfaces, the bumper nose extends the pig’s lifespan, improves its ability to navigate bends and obstructions, and enhances overall reliability during cleaning or inspection runs.

In contrast, pigs without a bumper nose are more susceptible to wear, misalignment, and mechanical failure, especially in abrasive or complex pipeline environments. The absence of a protective front end can lead to higher maintenance costs, increased downtime, and the risk of losing or damaging expensive equipment. Therefore, incorporating a bumper nose is a cost-effective and practical upgrade that enhances both performance and durability.

-300x300.jpg) Foam Pig With Brushes

Foam Pig With Brushes  Pipe Pigs For Pipeline Maintenance

Pipe Pigs For Pipeline Maintenance

_032003200_4429.jpg)

Reviews

There are no reviews yet.