Description

Our EMT company has 30 years of experience providing piping tools. We provide different types of quick opening closures. In this article, we mainly talk about 3 types of Quick Opening Closures.

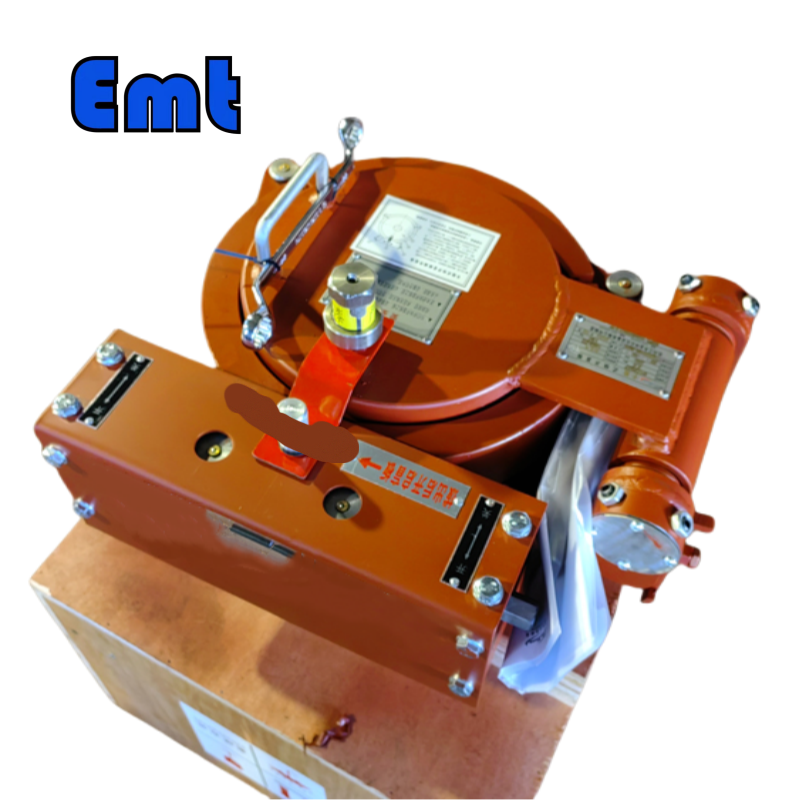

Bayonet Type Quick Opening Closure

The Bayonet Type Quick Opening Closure is an essential device tailored for securing and accessing pressure vessels and pipelines efficiently. Designed for industries like oil and gas, petrochemicals, and water treatment, it caters to environments requiring frequent internal access. This type of closure utilizes a straightforward twist-and-lock mechanism, allowing for rapid opening and closing, which is critical for regular maintenance or inspection routines.

Engineered with a focus on safety, these closures ensure a reliable seal capable of withstanding high pressures and harsh conditions. They commonly incorporate safety interlocks to prevent accidental openings when under pressure, enhancing operational safety. Made from durable materials such as stainless steel or carbon steel, bayonet closures withstand heavy industrial use and extreme environmental conditions, ensuring long-term reliability.

In addition to their robustness, bayonet closures offer ease of installation, which expedites setup and reduces labor costs. Their design promotes versatility, adapting to various vessel sizes and configurations, thus serving a broad range of applications. Whether used for routine checks, cleaning, or emergency interventions, Bayonet Type Quick Opening Closures maintains high standards of efficiency and safety across diverse industries.

Lockring Type Quick Opening Closure

The Lockring Type Quick Opening Closure (QOC) is a pivotal mechanism in managing operational access to pressure vessels and tanks. It is ideal for sectors that necessitate frequent and rapid access, such as the oil, gas, and chemical processing industries. This closure system uses a mechanical lockring that ensures a tight and secure seal, enabling quick and safe openings and closings crucial for maintaining smooth operations.

Designed with high safety standards, the Lockring Type QOC features robust mechanisms to prevent accidental openings. This includes safety locks that must be fully disengaged before the closure can open. Thereby you should ensure that it operates safely under high-pressure conditions. The use of durable materials like carbon steel or stainless steel enhances its suitability for enduring the demanding conditions of industrial environments.

Moreover, the design of the Lockring Type QOC simplifies the installation process, facilitating quick assembly without the need for specialized skills. This efficiency in setup helps reduce downtime and labor costs, contributing to overall operational cost savings. Versatile and reliable, this type of closure supports a wide range of applications and remains integral to enhancing safety and productivity in industrial settings.

Clamp Type Quick Opening Closure

Clamp Type Quick Opening Closure

The Clamp Type Quick Opening Closure is an indispensable tool for industries requiring fast and frequent access to pressurized vessels. Commonly used in the oil, gas, and petrochemical sectors, this closure features a hinged clamp mechanism that allows for rapid opening and secure closing. Its design caters specifically to operations where time efficiency and quick access are crucial.

Safety is a paramount concern with the Clamp Type Quick Opening Closure. It integrates multiple safety features to ensure a secure operation under high-pressure conditions. These include safety interlocks and pressure warnings that prevent the opening of the clamp while the system is pressurized, thereby reducing the risk of accidents.

Additionally, the Clamp Type Quick Opening Closure is known for its ease of installation and maintenance. It requires minimal tools for setup and you can operate it by a single person, which substantially lowers labor costs. Its robust construction and adaptability make it a preferred choice for a variety of industrial applications.

Clamp Type Quick Opening Closure

Clamp Type Quick Opening Closure

Reviews

There are no reviews yet.