Description

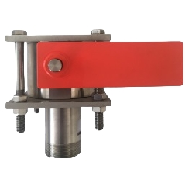

A Popper Pig Signaller, also known as a Popper Pig Detector or Popper Pig Passage Indicator, is a specialized device used in pipeline systems to confirm the passage of pipeline pigs. These devices are essential for ensuring the efficiency and safety of pigging operations, which involve sending pigs through pipelines for cleaning, inspection, or maintenance.

Installation and Operation

Popper Pig Signallers are typically installed on pig launchers or receivers, as well as at various points along the pipeline. Installation involves using a welded fitting or nipple that houses a trigger mechanism extending into the pipeline. When a pig passes by the signaller, the trigger mechanism activates a signal, confirming the pig’s passage at that specific location.

EMT Pig Signallers Indicator Types

| Indicator Types | ||||

|  |  |  | |

| Indicator Types | A | B | C | D |

| Intrusive Type | Intrusive | Intrusive | Intrusive | Non-intrusive |

| Indicator Features | Popper Type | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals |

Applications

Popper Pig Signallers are used in various industries, including oil and gas, water treatment, and chemical processing. They are particularly valuable in ensuring that cleaning and inspection pigs successfully navigate through the pipeline, providing operators with the necessary information to maintain pipeline integrity.

In addition to confirming pig passage, Popper Pig Signallers can help identify if a pig is lost or stuck by noting the lack of signal at expected intervals. This capability allows operators to quickly diagnose and address issues, minimizing downtime and maintenance costs.

Parameters

| Type: Intrusive |

| Connection type: Welded/Flange connection |

| Indicator feature: Manual reset flag combined with electrical signals (Manual reset flag and Date and time display combined with electrical signals can also be made) |

| Installing type: 2” Flange. As per ASME B16.5(CLASS150-2500) |

| Plug body length: 200mm/Meet the actual needs |

| Insert depth adjustment: 20mm |

| Operating temperature: -20~120℃/Meet customer requirements |

| NACE MR 0175: Yes |

| Ingress protection: IP66 |

| Explosion-proof class: Exd II BT4 |

| Remove under pressure: No |

| Trigger type: Bi-directional (Uni-directional trigger can also be made) |

| Internal part material: PTFE Coated A105N is standard configuration (304SS/316LSS/DSS/INCONEL/As per MR can meet customer needs) |

| Junction box material: Aluminium alloy/316SS |

| Switch type: DPDT/2*SPDT |

| Switch rating: DC24V 3A/DC24V 5A |

Key Features and Benefits

Popper Pig Signallers provide precise confirmation of pig passage, ensuring operators know exactly when a pig has moved past a certain point in the pipeline. These signallers are constructed from high-quality materials. They are designed to withstand harsh environmental conditions, including high pressure and extreme temperatures. When a pig passes the signaller, it triggers an immediate signal. This signal can be visual, audible, or transmitted to a control system. It allows operators to monitor pigging operations in real-time. By confirming the passage of pigs at various points along the pipeline, these devices maintain efficient operations. They help prevent potential issues related to blockages or debris buildup. Popper Pig Signallers are designed for straightforward installation with minimal intrusion into the pipeline, reducing setup time and labor costs.

Popper Pig Signallers also enhance safety in pipeline operations. They ensure operators receive timely alerts about pig movement. This immediate feedback helps prevent potential pipeline issues. Additionally, operators can quickly respond to any irregularities detected. These signallers integrate seamlessly with existing monitoring systems. This integration allows for centralized control and oversight. Moreover, their robust construction reduces the risk of malfunction. This reliability is crucial for maintaining continuous pipeline operations. Regular maintenance becomes easier with precise pig passage data. Operators can schedule maintenance activities more efficiently. Ultimately, Popper Pig Signallers contribute to smoother and safer pipeline management.

Reviews

There are no reviews yet.