Description

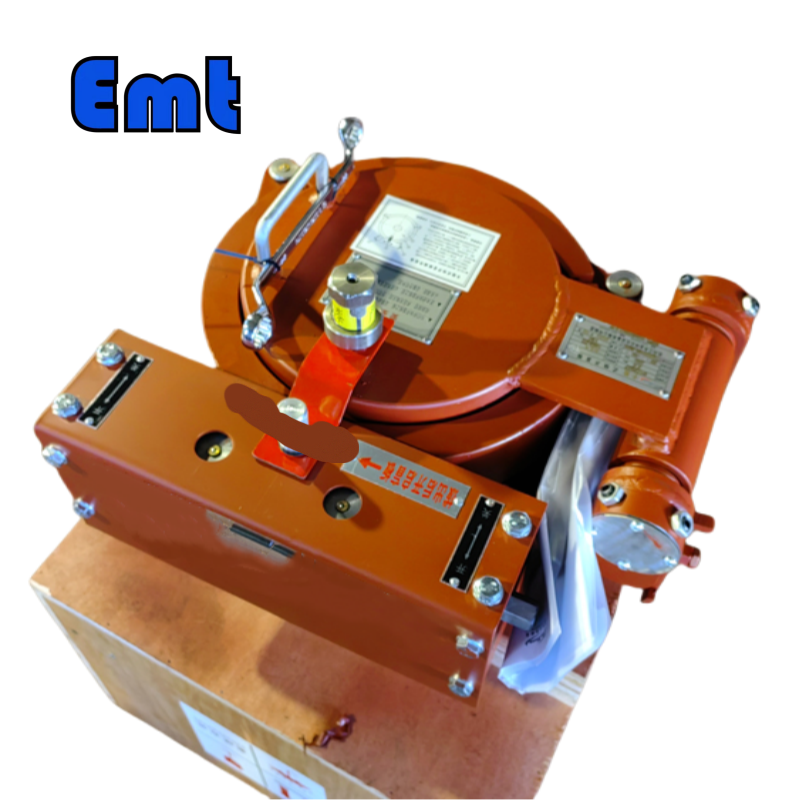

Introduction to Quick Opening Closure Band Lock

The Quick Opening Closure Band Lock is one of the closures. Compared with other types of quick-opening closures, this type can be operated safely at remarkable speed. Any unit size can be opened or closed in less than a minute, requiring no special tools.

The versatility of the Quick Opening Closure Band Lock allows the easy supply of variations from the standard. Besides offering Flanged Closure options, we also provide extensions for pig receivers and launchers to support intelligent pigging operations, along with custom-designed receiving cassettes tailored to specific operational needs.

Specifications of Quick Opening Closure Band Lock

| Technical indicators | |

| Nominal Diameter (DN): | <1800mm |

| Design pressure (PN): | ≤40 MPa |

| Working Medium: | oil, gas, and water |

| Design Temperature: | -50℃~300℃ |

| Material: | 16Mn, A350LF2, A105, SS304, SS316, F51, F53, F55, INCONEL625, HASTELLOY C |

| Pipe Thickness: | 6mm~100mm |

Materials

- ASTM A105 / ASME II SA105

- A350LF2

- ASTM A694 F42 to ASTM A694 F70

- Grade 304L or 316L Stainless Steel

- Duplex Stainless Steel (F51, F53 and F55)

- INCONEL625

- HASTELLOY C

Other materials are also available. (Contact us to have a further talk.)

Applications

The EMT Quick Opening Closure Band Lock type provides horizontal or vertical access to customers. Operators can open or close it in seconds. Compared with other quick-opening closures, they are safer and have remarkable speed. Operators can open or close any size of the unit in less than one minute without using any special tools. Designers used finite element analysis techniques and strain gauge validation tests to reduce the weight of the main pressure loading section while still complying with the main pressure vessel specifications. The tried-and-tested locking mechanism features a duplex stainless steel conical thrust ring, mounted between the door and the hub, that evenly distributes the pressure load across the entire 360° circumference of the hub.

Benefits of Using Band Locks

Enhanced Safety Features

Quick Opening Closure (QOC) Band Locks significantly enhance safety in industrial environments. They feature robust locking mechanisms that prevent accidental openings under high-pressure conditions. The use of high-grade materials like INCONEL625 and HASTELLOY C ensures exceptional resistance to corrosion and wear, reducing the risk of failure. Moreover, the design adheres to strict industry standards, providing reliable performance in extreme conditions ranging from -50 °C to 300 °C. Each closure undergoes rigorous testing to ensure it can withstand pressures up to 40 MPa, giving operators confidence in their safety protocols.

Operational Efficiency Improvements

QOC Band Locks excel at boosting operational efficiency. Their quick-opening mechanism allows for rapid access to the contents of a pipeline or vessel, significantly cutting down on maintenance and inspection times. The wide range of compatible materials, from 16Mn to Duplex Stainless Steel, makes these locks versatile for various mediums, including oil, gas, and water. This adaptability reduces downtime, as workers can quickly adapt to different working conditions without the need for extensive equipment changes. Additionally, the ability to handle pipe thicknesses ranging from 6 mm to 100 mm offers flexibility in application, ensuring that industries can optimize their operations for speed and effectiveness.

Daily Maintenance

To ensure a nice working condition and avoid blocking the operation, the following maintenance is a must:

- Notice: Any flaw in the sealing groove, sealing surface, or sealing ring will lead to leakage of the medium.

Therefore, neglecting routine inspections and paying less attention to daily maintenance is very dangerous.

Lock Ring

a) Wipe up the lock ring and check the corrosion condition of the surface. If there is any rust, treat it first, and then apply grease to prevent rust. If the material of the lockring is stainless steel, please neglect this.

b) Check if there is any deformation of the lockring and renting plate.

c) Check the installation of the locking plate to make sure it is correct.

Quick Opening Closure Band Lock Body

a) Fully inspect the headcover and cylinder flange after wiping it up. Check if there is any damage or defect; if yes, deal with it immediately.

b) Take off the lockring and check the location of the headcover to make sure it is centered. The allowable deviation is 0.2 mm.

Safety Bolt

a) After wiping the safety bolt clean, check whether the sealing surface, sealing groove, and sealing washer are damaged or missing

Trap. If the sealing surface or sealing groove has any damage or defections, it should be treated immediately. If there is any damage or defect, replace it immediately.

b) Visually check whether the internal thread matching the safety bolt is intact.

c) Check the fit of the safety bolt with the bolt hole.

Locking Mechanism

a) Lock the Quick Opening Closure Band Lock. Then check whether the locking gap is less than 5 mm. If it does not meet the requirement, reset the locking gap by adjusting the eccentric, tighten the bolt after adjustment, and fix the eccentric.

b) Check whether the limit nut has an excessive wear phenomenon; if there is more serious wear, you should replace it immediately.

Sealing

a) Check that the seal ring is intact; if found, damage or defects should be replaced immediately. The service life of the seal ring is 12 months. It should be necessary to ensure that the sealing ring is used within the validity period.

b) Evenly apply a layer of lubricating oil (glycerin, petroleum jelly, or anti-rust oil can be applied) to the sealing surface and sealing tank, and then reinstall the sealing ring into the sealing tank.

Leakage Test

a) After completing the above inspection, the pressure test is carried out. The test pressure value is shown on the product nameplate (5 times the design pressure).

.jpg)

Reviews

There are no reviews yet.